Embarking on the journey of creating a thriving high-tech planted aquarium often leads to the crucial step of implementing a CO2 injection system. This guide is meticulously crafted to demystify the process, offering a comprehensive walkthrough from selecting the right components to fine-tuning your system for optimal aquatic plant health and vibrant growth. Understanding the fundamental role of carbon dioxide in photosynthesis is the first step towards unlocking the full potential of your underwater garden.

This detailed exploration will cover everything from the essential hardware, such as CO2 cylinders, regulators, and diffusers, to the critical operational aspects like leak prevention, pressure settings, and timing. We will delve into the nuances of diffuser selection, monitoring tools, and the delicate art of adjusting CO2 levels, ensuring your plants receive the perfect balance of this vital nutrient. Furthermore, we will address common troubleshooting scenarios and essential safety considerations, empowering you to maintain a stable and flourishing ecosystem.

Introduction to CO2 Injection for Planted Tanks

Carbon dioxide (CO2) is an essential nutrient for aquatic plants, playing a fundamental role in their growth and overall health within an aquarium environment. Just as terrestrial plants utilize atmospheric CO2 for photosynthesis, aquatic plants require dissolved CO2 in the water column to fuel this vital process. Without adequate CO2 levels, even with optimal lighting and nutrients, plant growth will be significantly stunted, leading to less vibrant and aesthetically pleasing aquascapes.Supplementing CO2 in a high-tech planted aquarium is a cornerstone practice for achieving lush, dense plant growth and vibrant coloration.

In a well-maintained planted tank, plants are the primary inhabitants, and their health and vigorous growth are paramount. CO2 enrichment directly impacts the rate of photosynthesis, enabling plants to convert light energy and nutrients into biomass more efficiently. This leads to faster growth, stronger stems, more robust leaves, and often, the development of richer, more intense colors in plant species that exhibit them.

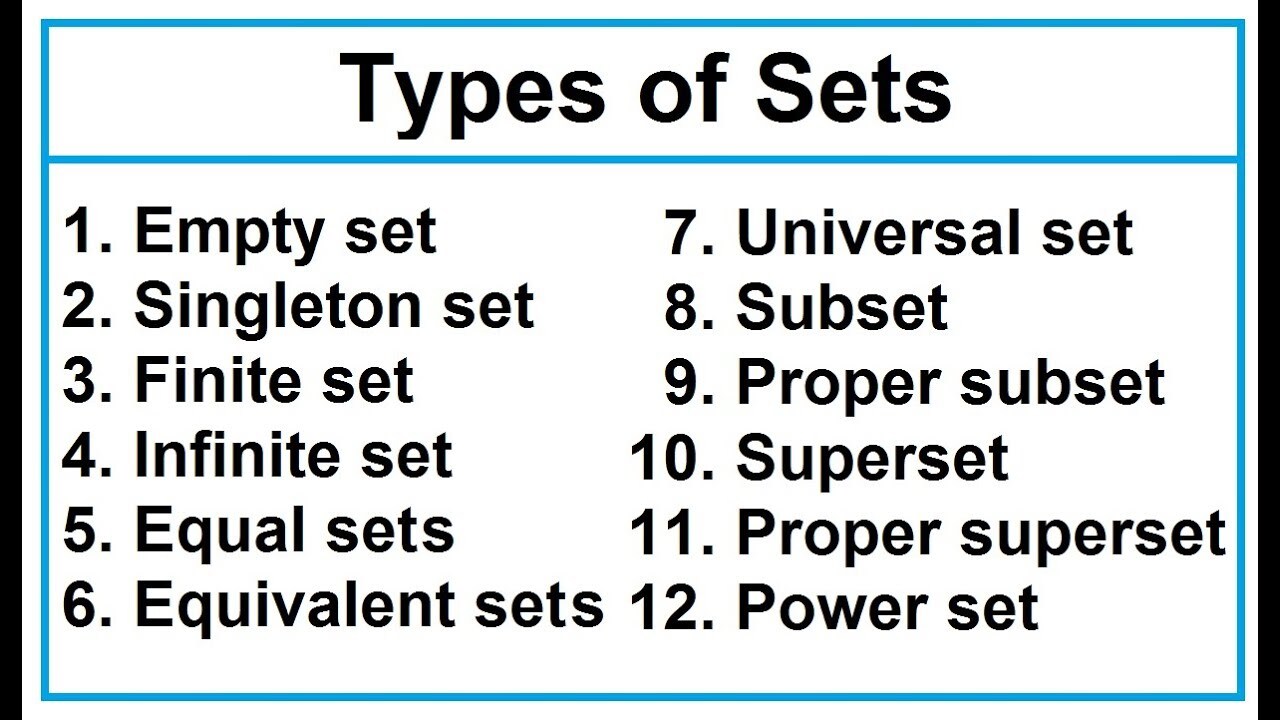

Furthermore, healthy plant growth helps to outcompete nuisance algae for nutrients, contributing to a cleaner and more balanced aquarium ecosystem.A typical CO2 injection system comprises several key components, each serving a specific purpose in delivering a controlled and consistent supply of carbon dioxide to the aquarium water. Understanding these components is crucial for setting up and maintaining an effective system.

Essential Components of a CO2 Injection System

The successful implementation of CO2 supplementation relies on a coordinated effort from several distinct parts of the system. Each component is designed to work in synergy to provide a safe and effective delivery of CO2 to the aquatic environment.A standard CO2 injection setup for planted aquariums generally includes the following core components:

- CO2 Cylinder: This is the primary source of carbon dioxide. Cylinders come in various sizes, from small disposable cartridges to larger refillable tanks, typically made of aluminum or steel. The choice of cylinder size often depends on the aquarium’s volume and the desired duration between refills.

- Regulator: Attached to the CO2 cylinder, the regulator reduces the high pressure of the gas within the cylinder to a safe and usable working pressure. It often includes a gauge to monitor the remaining CO2 in the cylinder and another to display the output pressure.

- Solenoid Valve: This is an electrically controlled valve that allows for the automation of CO2 injection. When connected to a timer, it can automatically shut off the CO2 supply during the lighting period and turn it off when the lights are off, preventing potential CO2 buildup during dark hours.

- Bubble Counter: A simple device used to visualize the flow rate of CO2 gas. It typically consists of a small chamber filled with water or a special liquid, where incoming CO2 bubbles can be counted per minute, allowing for precise adjustments to the injection rate.

- Check Valve: This safety device prevents aquarium water from being siphoned back into the CO2 system, which could cause damage to the regulator or cylinder. It allows gas to flow in only one direction.

- CO2 Tubing: Flexible, inert tubing, usually made of silicone or PVC, that connects the various components of the system and carries the CO2 gas from the cylinder to the aquarium.

- Diffuser: This is the component that introduces the CO2 gas into the aquarium water. Diffusers create very fine bubbles, maximizing the surface area for CO2 to dissolve into the water. Common types include ceramic disc diffusers and in-line diffusers that attach to canister filter output.

The precise function of each component is critical for maintaining a stable and beneficial CO2 level for plant growth.

CO2 Cylinder Selection and Setup

Selecting the right CO2 cylinder and setting it up correctly are crucial steps for a successful high-tech planted tank. This process involves understanding cylinder sizes, proper regulator connection, ensuring a leak-free seal, and establishing initial pressure settings. A well-chosen and properly installed CO2 system will provide a stable and consistent supply of carbon dioxide, essential for vigorous plant growth.

CO2 Cylinder Size Selection

The size of your CO2 cylinder should be determined by the volume of your aquarium and the rate at which you plan to inject CO2. Larger tanks and higher CO2 injection rates will necessitate larger cylinders to ensure a longer duration between refills. It is generally more cost-effective to purchase larger cylinders, even for smaller tanks, as the cost per unit of CO2 is lower.To help you make an informed decision, consider the following guidelines:

- For smaller tanks (e.g., up to 20 gallons): A smaller cylinder, such as a 5 lb or 10 lb capacity, might suffice. These are more compact and easier to handle.

- For medium tanks (e.g., 20-55 gallons): A 10 lb or 20 lb cylinder is a common and practical choice, offering a good balance between capacity and size.

- For larger tanks (e.g., 55 gallons and above): A 20 lb or larger cylinder is recommended. This will provide extended periods between refills, reducing the inconvenience of frequent exchanges.

It is also important to consider the available space for the cylinder. Some cylinders are quite tall and may require dedicated floor space or a secure stand.

CO2 Regulator Connection to Cylinder

Connecting the CO2 regulator to the cylinder is a straightforward process that requires attention to detail to ensure safety and functionality. The regulator reduces the high pressure from the cylinder to a usable, lower pressure for your aquarium system.The connection typically involves the following steps:

- Ensure the cylinder valve is fully closed before attaching the regulator.

- Remove any protective cap from the cylinder valve outlet.

- Align the regulator’s inlet with the cylinder valve outlet. Most regulators have a built-in washer or gasket that needs to seat properly against the valve.

- Hand-tighten the regulator onto the cylinder valve. Do not overtighten with tools at this stage.

- Once hand-tight, use a wrench to give it an additional quarter to half turn. This ensures a secure fit without damaging the threads.

The regulator will typically have a main pressure gauge indicating the pressure remaining in the cylinder and a secondary gauge or a needle valve assembly to control the bubble rate.

Ensuring a Leak-Free Seal

A leak-free seal is paramount to prevent the rapid depletion of your CO2 supply and to ensure the safety of your system. Leaks can occur at the connection point between the regulator and the cylinder, or at other connection points within your CO2 line.To achieve and verify a leak-free seal:

- Use the provided washer/gasket: Most regulators come with a soft washer or gasket that is essential for creating a seal. Ensure this is present and in good condition before connecting.

- Hand-tighten first: As mentioned, hand-tighten the regulator as much as possible. This allows you to feel for proper thread engagement and alignment.

- Wrench tightening: Use a wrench for the final snugging, but avoid excessive force.

- Leak detection: After connecting and before opening the cylinder valve, it is advisable to perform a leak test. A common method is to use a solution of soapy water. Apply the soapy water around the connection point. If bubbles appear when the cylinder is opened, there is a leak.

- Tighten if necessary: If a leak is detected, close the cylinder valve, and gently tighten the regulator connection slightly. Re-test with soapy water.

A properly sealed connection will prevent CO2 from escaping and ensure that your system operates efficiently and safely.

Initial Regulator Pressure Settings

Once the regulator is securely connected and confirmed to be leak-free, the next step is to set the initial working pressure. This is typically done by adjusting the regulator’s control knob. The goal is to set a stable working pressure that your bubble counter can effectively utilize.The process for initial pressure settings is as follows:

- Ensure the cylinder valve is fully open.

- Slowly open the regulator’s control knob. You will see the pressure gauge on the regulator begin to rise.

- Adjust the control knob until the desired working pressure is achieved. For most aquarium CO2 regulators, a working pressure between 20-40 PSI is common. Consult your regulator’s manual for specific recommendations.

- Once the pressure is set, you can then adjust the needle valve to control the CO2 bubble rate into your aquarium.

The pressure gauge on the regulator indicates the output pressure from the regulator, which should remain relatively constant as long as there is sufficient CO2 in the cylinder. This stable pressure allows for precise control of the bubble rate.

The ideal working pressure is one that allows your needle valve to provide consistent CO2 delivery without excessive fluctuations.

Regulator and Solenoid Valve Integration

The integration of a solenoid valve into your CO2 system is a crucial step that allows for automated control of CO2 injection, synchronizing it with your aquarium’s lighting cycle. This automation is vital for maintaining stable CO2 levels and preventing potential issues.The solenoid valve acts as an electrically controlled on/off switch for your CO2 supply. When energized by an electrical current, it opens, allowing CO2 to flow from the regulator to your aquarium.

When the current is interrupted, it closes, shutting off the CO2 supply. This functionality is primarily used to turn off CO2 injection when the aquarium lights are off, mimicking natural conditions and preventing over-saturation of CO2, which can be detrimental to fish and plant health.

Solenoid Valve Connection and Timer Setup

Proper connection and timing are essential for the solenoid valve to function effectively within your CO2 system. This ensures that CO2 is supplied only when your plants can utilize it through photosynthesis.To connect the solenoid valve, it is typically installed in-line between the CO2 regulator and the check valve. The regulator’s output is connected to the inlet of the solenoid valve, and the outlet of the solenoid valve is then connected to the aquarium’s check valve.

The solenoid valve itself will have electrical connections, usually a plug and a socket, which will be wired to a timer.The necessity of a timer for solenoid valve operation stems from the fact that plants require CO2 for photosynthesis, a process that occurs primarily when lights are on. By connecting the solenoid valve to an aquarium light timer, you can program the CO2 to be supplied only during the hours your lights are on.

This not only conserves CO2 but also prevents a drop in pH when lights are off, which can stress aquatic life. Setting the timer involves configuring the on and off times to coincide with your lighting schedule. For example, if your lights are on from 10 AM to 8 PM, you would set the timer to energize the solenoid valve from 10 AM to 8 PM.

Solenoid Valve Positioning Best Practices

Strategic placement of the solenoid valve ensures ease of access for maintenance and promotes a safer operating environment for your CO2 system.Consider the following best practices for positioning your solenoid valve:

- Accessibility: Mount the solenoid valve in a location that is easily accessible for maintenance, adjustments, or replacement without needing to dismantle significant portions of the CO2 setup. This is particularly important if you need to troubleshoot or perform routine checks.

- Safety: Position the solenoid valve away from direct water splashes or areas prone to moisture. While most solenoid valves are designed to be robust, prolonged exposure to water can lead to corrosion or electrical issues. Ensure electrical connections are secure and protected.

- Proximity to Regulator: While not strictly mandatory, placing the solenoid valve relatively close to the CO2 regulator can minimize the length of high-pressure tubing, which can sometimes simplify the overall setup and reduce potential leak points.

- Ventilation: Ensure the area around the solenoid valve has adequate ventilation, especially if it is an older model or one that tends to generate a small amount of heat when energized.

CO2 Tubing and Check Valve Installation

With the essential components of your CO2 system in place, the next crucial steps involve connecting them securely and safely. This section will guide you through selecting the right tubing, understanding the vital role of a check valve, and ensuring a leak-free setup. Proper installation here prevents issues down the line and ensures consistent CO2 delivery to your aquatic plants.

CO2 Tubing Options

The tubing is the lifeline of your CO2 system, carrying the gas from the cylinder to your aquarium. Choosing the appropriate material is important for durability, flexibility, and preventing leaks. Different types of tubing offer distinct advantages and disadvantages for planted tank enthusiasts.

- Silicone Tubing: This is a popular choice due to its extreme flexibility and ease of use. It’s very forgiving when routing around equipment and plants. However, silicone can sometimes be more prone to kinking if bent too sharply, and some aquarium hobbyists report a slight CO2 permeability over very long periods, though this is generally not a significant concern for typical tank setups.

- PU (Polyurethane) Tubing: PU tubing is known for its excellent resistance to kinking and its durability. It’s often a bit stiffer than silicone but still manageable. It offers a good balance of flexibility and rigidity, making it a reliable option for CO2 lines. PU tubing is generally considered to have very low CO2 permeability.

- PVC Tubing: While common in other aquarium applications, standard PVC tubing is generally not recommended for CO2 systems. It can become brittle over time, especially when exposed to CO2, and is prone to cracking. Specific CO2-rated PVC tubing might exist, but silicone and PU are more widely adopted and trusted for this purpose.

The Importance of a Check Valve

A check valve is an indispensable safety device in any CO2 injection system. Its primary function is to prevent water from siphoning back into your CO2 regulator and cylinder. This is critical because water ingress can cause significant damage to the delicate internal components of the regulator, leading to malfunction or complete failure.

The check valve acts as a one-way gate, allowing CO2 to flow towards the aquarium but blocking any reverse flow of water.

Check Valve Placement

Correct placement of the check valve is paramount to its effectiveness. It should be installed in the CO2 line between the regulator and the point where the CO2 enters the aquarium, typically before the diffuser. This ensures that any potential water backflow is stopped before it can reach the sensitive regulator components.The ideal placement is generally as close to the aquarium as possible, but before any bends or connections that could trap water.

Many CO2 regulators come with an integrated check valve, but it is always recommended to use an additional inline check valve for maximum protection, especially if your regulator does not have one or if you are using a very long CO2 line.

Securing Tubing for a Leak-Free System

Preventing leaks is crucial for both the efficiency of your CO2 system and the safety of your aquarium inhabitants. Loose connections can lead to a significant loss of CO2, making it difficult to maintain stable levels, and can also create a potential hazard.Here are some tips for securing your CO2 tubing:

- Use appropriate connectors: Ensure that the tubing fits snugly onto the barbed fittings of your regulator, solenoid valve, and check valve. If the tubing feels loose, consider using small zip ties or specialized tubing clamps to secure it firmly.

- Avoid sharp bends: Route your CO2 tubing in gentle curves. Sharp bends can restrict CO2 flow, create pressure points, and increase the likelihood of kinks or cracks developing over time. Use tubing clips or gently guide the tubing around aquarium equipment to achieve smooth transitions.

- Inspect regularly: Periodically check all connections for any signs of wear, hardening, or leaks. The lifespan of CO2 tubing can vary depending on the material and environmental conditions, so regular inspection is a good practice.

- Proper tension: While you want connections to be secure, avoid over-tightening or creating excessive tension on the tubing, as this can also lead to damage or leaks. The tubing should be taut enough to prevent disconnection but not strained.

Diffuser Selection and Placement Strategies

The diffuser is a crucial component in your CO2 system, responsible for breaking down the gas into fine bubbles that can be efficiently absorbed by the aquarium water. Choosing the right diffuser and placing it strategically can significantly impact CO2 distribution and plant growth. This section will guide you through the different types of diffusers, their optimal placement, and maintenance.

CO2 Diffuser Types and Effectiveness

Different diffuser types offer varying levels of CO2 dissolution and aesthetic appeal. Understanding their characteristics will help you select the best option for your specific aquarium setup.

Ceramic Disc Diffusers

These are the most common type, featuring a porous ceramic disc that atomizes CO2 into fine bubbles. The effectiveness is directly related to the fineness of the pores and the water flow across the ceramic surface. Smaller bubbles have a higher surface area to volume ratio, leading to better gas exchange.

Inline CO2 Reactors

Inline reactors are designed to be integrated into your filter’s outflow. CO2 is injected into the reactor, and the water flow from the filter churns the gas, dissolving it into micro-fine bubbles before it enters the aquarium. This method offers very high dissolution rates and keeps the aquarium free of visible bubbles.

Glass Bell Diffusers

These diffusers, often made of elegant borosilicate glass, feature a ceramic disc at the bottom. CO2 is injected into the bell, and as it rises through the ceramic, it’s broken into fine bubbles. They are aesthetically pleasing and allow for easy monitoring of CO2 levels as bubbles accumulate at the top.

Optimal Diffuser Placement

The placement of your CO2 diffuser directly influences how effectively the gas is distributed throughout the tank. The goal is to ensure that CO2 reaches all areas of the aquarium, especially where your plants are located, without creating dead spots or excessive surface agitation.The ideal placement is typically in the path of the filter’s water outflow. This ensures that the CO2 bubbles are immediately mixed with the water flow and dispersed throughout the tank.

Positioning the diffuser near the substrate can also be beneficial for plants rooted there, but it’s important to avoid placing it directly in front of strong currents that might blow the bubbles away too quickly. For inline reactors, placement is determined by your filter setup, usually in the tubing between the filter and the aquarium.

Factors Influencing Bubble Size and Diffusion Efficiency

Several factors contribute to the size of CO2 bubbles produced by a diffuser and how efficiently they dissolve into the water.

- Pore Size (Ceramic Diffusers): The smaller the pores in a ceramic disc, the finer the bubbles produced. Finer bubbles have a larger surface area, which increases the rate of CO2 diffusion into the water.

- Water Flow: Adequate water flow across the diffuser surface is essential for breaking up larger bubbles and promoting dissolution. This is why placing diffusers in the filter outflow is recommended.

- Pressure: The CO2 pressure from the regulator influences the initial bubble formation. Higher pressure can help push CO2 through finer pores, creating smaller bubbles.

- Water Chemistry: Factors like water temperature and the presence of surface film can affect diffusion rates.

CO2 Diffuser Cleaning and Maintenance

Over time, diffusers can become clogged with algae or mineral deposits, reducing their effectiveness. Regular cleaning is vital to maintain optimal CO2 diffusion.For ceramic disc diffusers, a common cleaning method involves soaking them in a diluted bleach solution (e.g., 1 part bleach to 10 parts water) for a few hours or overnight. After soaking, rinse thoroughly with clean water and let them air dry completely before reinstallation.

Some aquarists also use a dilute hydrochloric acid (muriatic acid) solution for stubborn clogs, but extreme caution and proper ventilation are necessary.Inline reactors generally require less frequent cleaning, as the water flow helps to keep them clear. However, if you notice reduced CO2 dissolution, you may need to disassemble and clean the reactor according to the manufacturer’s instructions.

Diffuser Type Comparison

The following table provides a comparison of common CO2 diffuser types to assist in your selection process.

| Diffuser Type | Ideal Tank Size (Gallons) | Typical Bubble Size | Pros | Cons |

|---|---|---|---|---|

| Ceramic Disc | 10-75 | Fine (2-5mm) | Cost-effective, readily available | Can clog, requires regular cleaning |

| Inline Reactor | 20-150+ | Micro-fine (dissolved) | High dissolution rate, aesthetically pleasing | Requires pump/filter integration, higher cost |

| Glass Bell | 10-50 | Fine (1-3mm) | Aesthetically pleasing, easy to monitor | Fragile, can be less efficient in larger tanks |

CO2 Metering and Monitoring Tools

Accurately metering and monitoring CO2 levels in your planted aquarium is crucial for maintaining optimal plant growth and fish health. Without proper oversight, you risk either insufficient CO2 leading to plant deficiencies or excessive CO2, which can be detrimental to your aquatic inhabitants. This section will guide you through essential tools for CO2 management.The primary goal of CO2 monitoring is to ensure a stable and appropriate concentration within the aquarium water.

This balance is often described in terms of parts per million (ppm). For most high-tech planted tanks, a target range of 20-30 ppm is considered ideal for robust plant growth. Deviations outside this range can signal issues with your CO2 injection system or the aquarium’s overall environment.

CO2 Drop Checker Function and Interpretation

A CO2 drop checker is a simple yet indispensable tool for visually assessing CO2 levels in your planted aquarium. It consists of a small glass or plastic vessel that holds a reagent solution and is typically placed inside the aquarium, often near the CO2 diffuser or in the water flow. The reagent changes color based on the concentration of dissolved CO2 in the aquarium water, which is in equilibrium with the CO2 in the air within the drop checker.To properly use a CO2 drop checker:

- Fill the drop checker’s reservoir with the provided reagent solution. Some solutions require dilution with aquarium water; always follow the manufacturer’s instructions.

- Place the drop checker in your aquarium, ensuring it is fully submerged and exposed to the aquarium water.

- Allow sufficient time for the color to stabilize. This can take anywhere from 30 minutes to a few hours, depending on the aquarium’s water parameters and CO2 injection rate.

Interpreting the color indicator is straightforward:

- Blue: Indicates low CO2 levels. The aquarium is likely receiving insufficient CO2, which can hinder plant growth.

- Green: Indicates optimal CO2 levels, typically within the desired 20-30 ppm range. This is the target color to aim for.

- Yellow: Indicates high CO2 levels. This can be harmful to fish and other aquatic life. If you observe a yellow color, reduce your CO2 injection rate and monitor the situation closely.

It is important to note that the reagent’s color may vary slightly depending on the pH and KH (carbonate hardness) of your aquarium water. However, the general trend of blue for low, green for good, and yellow for high remains consistent.

pH Controller or Monitor for CO2 Regulation

While a drop checker provides a visual cue, a pH controller or monitor offers a more precise and automated method for regulating CO2 levels. These devices measure the aquarium’s pH, which is directly influenced by the amount of dissolved CO2. As CO2 dissolves in water, it forms carbonic acid, lowering the pH.The advantages of using a pH controller or monitor for CO2 regulation include:

- Automated Control: A pH controller can automatically turn your CO2 solenoid valve on and off to maintain a set pH range, ensuring consistent CO2 delivery.

- Precise Regulation: By targeting a specific pH value (e.g., 6.5-6.8, which corresponds to a healthy CO2 level), you can achieve more stable CO2 concentrations than with manual adjustment or a drop checker alone.

- Safety Features: Many pH controllers have built-in safety mechanisms, such as maximum run times for the CO2 solenoid, to prevent dangerous drops in pH.

- Data Logging: Some advanced monitors can log pH readings over time, allowing you to track trends and identify potential issues.

When using a pH controller, you will typically set a target pH and a hysteresis (or deadband). For example, you might set a target pH of 6.7 with a hysteresis of 0.2. The controller would then turn the CO2 on when the pH rises above 6.8 and turn it off when the pH drops below 6.6. This constant adjustment helps maintain the desired CO2 level.

Calibration of CO2 Monitoring Equipment

Proper calibration of your CO2 monitoring equipment, particularly pH controllers and monitors, is essential for accurate readings and effective CO2 regulation. Calibration ensures that the device’s sensors are providing precise measurements.The calibration process for pH meters and controllers typically involves using specialized calibration solutions, often referred to as buffer solutions. These solutions have known, stable pH values.

- Calibration Solutions: You will need at least two calibration solutions, typically pH 4.0 and pH 7.0. Some advanced meters may require a third, such as pH 10.0.

- Cleaning: Before calibration, ensure the pH probe is clean and rinsed with distilled or deionized water.

- Calibration Steps: Follow the specific instructions provided by the manufacturer of your pH meter or controller. Generally, this involves immersing the probe in the first calibration solution (e.g., pH 7.0) until the reading stabilizes, then rinsing and immersing it in the second solution (e.g., pH 4.0). The device will then adjust its internal settings based on these known values.

- Frequency: pH probes should be calibrated regularly, typically every 1-3 months, or whenever you notice inconsistent readings or if the probe has been stored for an extended period.

For CO2 drop checkers, calibration is not typically performed as they rely on a chemical reaction with the reagent. However, ensuring the reagent is fresh and properly prepared according to the manufacturer’s instructions is crucial for accurate color indication. If you suspect your drop checker reagent is no longer effective, it’s best to replace it.

Initial CO2 Injection and Adjustment

The moment has arrived to introduce CO2 into your planted aquarium. This crucial step requires careful observation and gradual adjustment to ensure a healthy environment for your aquatic plants and inhabitants. Proper initial CO2 injection is foundational for achieving vibrant plant growth and maintaining stable water parameters.Introducing CO2 for the first time into a planted tank is a process of careful calibration.

It involves systematically activating the system, observing the immediate effects, and making incremental adjustments. The goal is to reach an optimal CO2 level that promotes photosynthesis without stressing the fish or plants.

Step-by-Step Initial CO2 Injection Procedure

To safely and effectively begin CO2 injection, follow this detailed procedure. This methodical approach minimizes the risk of shocking your aquarium inhabitants and allows for precise tuning of the system.

- Connect all components securely: Before turning on the CO2 supply, double-check that all connections between the cylinder, regulator, solenoid valve, tubing, check valve, and diffuser are tight and leak-free. This prevents any accidental gas loss.

- Slowly open the CO2 cylinder valve: Gradually turn the main valve on the CO2 cylinder counter-clockwise. Listen for any hissing sounds that might indicate a leak. A slow opening prevents a sudden surge of pressure.

- Adjust the regulator to a low output pressure (e.g., 20-30 PSI): Set the regulator’s output pressure to a conservative level, typically between 20 and 30 PSI. This provides a controlled flow and allows for finer adjustments later.

- Turn on the solenoid valve: If your solenoid valve is connected to a timer, ensure the timer is set to activate during your desired lighting period. Manually turn on the solenoid valve to allow gas to flow through the system.

- Begin with a low bubble count (e.g., 1 bubble every 2-3 seconds): Start with a very low rate of CO2 delivery, approximately one bubble every two to three seconds from the diffuser. This minimal rate allows you to observe the system’s response without overwhelming the tank.

- Monitor drop checker and fish for 24 hours: Observe your CO2 drop checker’s color change over the next 24 hours. A healthy green color indicates optimal CO2 levels. Concurrently, watch your fish for any signs of distress, such as rapid gill movement, erratic swimming, or staying at the surface.

- Gradually increase BPS if needed, re-monitoring daily: If the drop checker remains blue or a pale blue after 24 hours, and fish behavior is normal, slowly increase the bubble count by one bubble every few seconds. Continue this gradual increase and daily monitoring until the drop checker consistently shows a green color, and fish remain active and healthy.

Observing Plant and Fish Behavior for CO2 Levels

The health of your aquarium’s inhabitants is the most direct indicator of proper CO2 levels. Understanding what to look for can help you fine-tune your system effectively.

Plants will exhibit signs of thriving when CO2 levels are adequate. You will notice an increase in pearling, which is the release of tiny oxygen bubbles from the leaves. New growth should appear vigorous, and leaves should maintain a healthy, deep green color. Conversely, if CO2 is too low, plant growth will be stunted, and leaves may appear pale or develop algae more readily.

Over-gassing, however, can be detrimental to both plants and fish. Plants may show signs of “burning” or wilting if the CO2 concentration becomes excessively high, while fish will show signs of distress as described previously.

Fine-Tuning Bubble Count Per Second (BPS) Based on Tank Parameters

The optimal bubble count per second (BPS) is not a fixed number but rather a dynamic value that depends on several aquarium-specific factors. These include the volume of the tank, the intensity and duration of your lighting, the type and density of your plant mass, and the water flow rate.

The ideal CO2 concentration for most high-tech planted tanks is between 20-30 ppm (parts per million), which typically corresponds to a pH drop of 0.2-0.4 units from its natural state, and a yellow to green color change on a standard pH drop checker.

A general guideline for initial BPS adjustment is to start low and increase incrementally. For instance, a 20-gallon tank might initially require 1-2 BPS, while a 50-gallon tank could start with 3-5 BPS. These are starting points, and daily observation is key. If your drop checker remains blue, indicating low CO2, you would increase the BPS. If it turns yellow, indicating too much CO2, you would decrease it.

The goal is to achieve a consistent green color by the end of the photoperiod. Factors like water changes can temporarily affect CO2 levels, so re-monitoring after such events is important.

Procedure for Initial CO2 Ramp-Up

This structured ramp-up process ensures a gradual and safe introduction of CO2 into your planted aquarium. Each step builds upon the previous one, allowing for continuous monitoring and adjustment.

- Step 1: Connect all components securely. Ensure all parts of your CO2 system, from the cylinder to the diffuser, are firmly connected to prevent any leaks.

- Step 2: Slowly open the CO2 cylinder valve. Turn the main valve on the CO2 cylinder counter-clockwise to allow gas to flow into the system. Listen for any unusual sounds.

- Step 3: Adjust the regulator to a low output pressure (e.g., 20-30 PSI). Set the regulator’s output pressure to a manageable level, typically between 20 and 30 PSI, to control the gas flow.

- Step 4: Turn on the solenoid valve. Activate the solenoid valve, usually via a timer synchronized with your aquarium lights, to permit CO2 injection.

- Step 5: Begin with a low bubble count (e.g., 1 bubble every 2-3 seconds). Start CO2 diffusion at a very low rate, such as one bubble per two to three seconds, to gauge the initial response of the system and inhabitants.

- Step 6: Monitor drop checker and fish for 24 hours. Observe the color of your CO2 drop checker and the behavior of your fish for a full day. Look for the characteristic green color in the drop checker and signs of healthy activity in the fish.

- Step 7: Gradually increase BPS if needed, re-monitoring daily. If the drop checker is not yet green and fish are healthy, slowly increase the bubble count per second. Continue this gradual adjustment and daily monitoring until the desired green color is achieved and maintained.

Maintaining and Troubleshooting the CO2 System

A well-maintained CO2 system is crucial for the health and vibrant growth of your high-tech planted aquarium. Regular checks and proactive maintenance can prevent common issues and ensure a stable CO2 environment for your aquatic plants. This section will guide you through identifying and resolving potential problems, along with a recommended maintenance schedule.

Common CO2 System Issues and Troubleshooting Steps

Even with careful setup, CO2 systems can encounter various problems. Understanding these common issues and their solutions will help you quickly restore optimal CO2 levels in your tank.

Leaks in the CO2 System

Leaks are one of the most frequent and frustrating problems. They can lead to inefficient CO2 delivery, pressure loss, and potential safety hazards.

- Identifying Leaks: The most effective way to find leaks is by using soapy water. Apply a generous amount of dish soap mixed with water to all connections, tubing, and fittings. Look for persistent bubbles, which indicate escaping CO2. You can also listen for a faint hissing sound.

- Troubleshooting:

- At the Cylinder Valve: Ensure the valve is fully tightened. If the leak persists, the valve itself might be faulty, requiring professional servicing or replacement.

- At Regulator Connections: Check that the regulator is properly seated on the cylinder and that the sealing washer is intact and correctly positioned. Tighten connections securely.

- At Solenoid Valve and Manifold Fittings: Ensure all fittings are hand-tightened, and if using threaded fittings, ensure Teflon tape has been applied correctly to prevent leaks.

- Along the Tubing: Inspect the CO2 tubing for any visible cracks, kinks, or pinholes. Ensure it’s securely attached to all fittings. Replace any damaged sections of tubing.

- At the Diffuser Connection: Verify that the tubing is firmly connected to the diffuser’s inlet.

Clogged CO2 Diffusers

A clogged diffuser will significantly reduce the effectiveness of your CO2 injection, leading to large, inconsistent bubbles or no bubbles at all.

- Identifying Clogs: You’ll notice large, irregular bubbles or a complete lack of fine mist. The ceramic disc of the diffuser may appear dirty or encrusted.

- Troubleshooting:

- Cleaning the Diffuser: The most common method is to soak the diffuser in a dilute bleach solution (1 part bleach to 9 parts water) for a few hours or overnight. Rinse thoroughly with clean water and allow it to air dry completely before reattaching. Alternatively, a strong vinegar solution can be used for less severe clogs. For persistent clogs, a specialized diffuser cleaning solution can be effective.

- Replacing the Diffuser: If cleaning does not resolve the issue, the ceramic disc may be permanently damaged or too heavily fouled, necessitating replacement.

Regulator Malfunctions

A malfunctioning regulator can lead to inconsistent pressure, no CO2 flow, or dangerously high pressure.

- Identifying Issues: The most common signs are a complete lack of bubble count, erratic bubble counts, or the pressure gauge not responding.

- Troubleshooting:

- Pressure Gauge Reading: If the working pressure gauge reads zero and the cylinder has CO2, the regulator may be faulty.

- Internal Valve Issues: Some regulators have internal valves that can become stuck. Gently tapping the regulator might temporarily resolve this, but it indicates a need for service or replacement.

- Professional Servicing: Regulators are precision instruments. If you suspect a serious malfunction, it’s best to have it serviced by a qualified technician or replace it. Attempting to repair it yourself can be dangerous.

Solenoid Valve Not Opening or Closing

The solenoid valve is essential for controlling CO2 injection, especially when linked to a timer.

- Identifying Issues: If CO2 is flowing 24/7 or not at all when it should be, the solenoid valve might be the culprit.

- Troubleshooting:

- Check Power Supply: Ensure the solenoid valve is properly plugged into a timer or power source and that the timer is functioning correctly.

- Listen for a Click: When the solenoid is supposed to be open, you should hear a faint click. If you don’t, it may not be receiving power or the coil might be burned out.

- Check for Obstructions: While less common, debris can sometimes impede the valve’s operation.

- Replacement: If power is confirmed and the valve still doesn’t operate, it likely needs to be replaced.

Recommended CO2 System Maintenance Schedule

Adhering to a regular maintenance schedule will keep your CO2 system running efficiently and safely.

- Weekly:

- Visually inspect all connections for leaks.

- Check the bubble count and ensure it is consistent.

- Monitor the drop checker’s color to confirm CO2 levels are within the target range (typically light green).

- Monthly:

- Clean the CO2 diffuser if it appears to be developing algae or mineral buildup.

- Check the CO2 cylinder pressure gauge.

- Inspect the CO2 tubing for any signs of wear, kinks, or damage.

- Every 3-6 Months (or as needed):

- Perform a more thorough leak test using soapy water on all connections.

- If using a reusable CO2 tank, consider having it professionally inspected and hydro-tested according to local regulations.

Refilling CO2 Cylinders

Running out of CO2 unexpectedly can disrupt your aquarium’s ecosystem. Planning for refills is essential.

- Exchange Services: The most common and convenient method for refilling standard aluminum CO2 cylinders (like those used for paintball or welding) is through exchange services. Many local welding supply stores, aquarium shops, or specialized gas suppliers offer this. You bring your empty cylinder and swap it for a full one, paying a refill fee.

- Professional Refilling: Some specialized gas suppliers can refill your cylinder on-site. This is often the case for larger, more permanent CO2 tanks used in industrial settings, but can also be an option for aquarium-specific cylinders.

- Safety Precautions: Always transport CO2 cylinders upright and secured to prevent them from falling. Ensure the valve is closed and, if possible, protected. When handling, wear appropriate gloves and eye protection.

Troubleshooting Guide for CO2 Systems

Problem: No CO2 bubbles are visible.

Possible Causes: Cylinder empty, valve closed, regulator malfunction, leak in the line, solenoid valve closed or not powered.

Solutions: Check cylinder pressure and ensure it’s above minimum refill level. Verify all manual valves are open. Inspect for leaks from cylinder to diffuser using soapy water. Confirm solenoid valve is receiving power and is in the open position.Check regulator output pressure. Problem: CO2 bubbles are too large or inconsistent.

Possible Causes: Clogged diffuser, low system pressure, faulty regulator, kink in tubing.

Solutions: Clean or replace diffuser. Check regulator output pressure and ensure it’s within the desired range. Inspect tubing for kinks or damage.Consider regulator service if issues persist. Problem: Drop checker remains blue (too little CO2).

Possible Causes: Insufficient bubble rate (BPS), CO2 leak, faulty check valve, insufficient lighting or plant mass, poor water circulation.

Solutions: Increase bubble rate gradually. Perform thorough leak checks. Test check valve functionality.Ensure adequate lighting and sufficient plant density for the tank size. Improve water flow to distribute CO2 effectively. Problem: Drop checker remains yellow (too much CO2).

Possible Causes: Excessive bubble rate (BPS), insufficient lighting or plant mass, poor water circulation, malfunctioning regulator.

Solutions: Reduce bubble rate gradually. Ensure adequate lighting intensity and photoperiod.Increase plant density. Improve water flow. Verify regulator is set to the correct output pressure and is functioning properly. Problem: Regulator gauge showing dropping pressure when cylinder is full.

Possible Causes: Leak at the cylinder valve connection, faulty regulator diaphragm, or a slow leak within the regulator.

Solutions: Perform a thorough leak test at the cylinder valve connection.If the leak is within the regulator, it requires professional servicing or replacement.

Safety Considerations for CO2 Systems

While a CO2 injection system is instrumental in achieving a thriving planted aquarium, it’s crucial to approach its implementation with a strong emphasis on safety. Elevated CO2 levels can pose significant risks to both aquatic life and human well-being if not managed correctly. Understanding these potential hazards and implementing appropriate safety measures is paramount for a successful and secure aquarium setup.The primary concern with CO2 injection is the potential for dangerously high concentrations of the gas to accumulate in the aquarium water.

This can rapidly overwhelm fish and other aquatic inhabitants, leading to a range of adverse effects. It is therefore essential to be aware of these risks and to take proactive steps to mitigate them.

Risks of High CO2 Concentrations in Aquariums

High levels of dissolved carbon dioxide in aquarium water can disrupt the natural physiological processes of fish and invertebrates. This disruption primarily affects their ability to respire effectively, as CO2 influences the pH of the water and can interfere with the oxygen-carrying capacity of their blood.The consequences of CO2 toxicity in fish can manifest in several ways:

- Rapid Gill Movement: Fish may exhibit rapid and labored breathing as they struggle to extract sufficient oxygen from the water.

- Lethargy and Gasping: A noticeable decrease in activity, with fish appearing listless or gasping at the surface, indicates distress.

- Loss of Equilibrium: In severe cases, fish may lose their ability to swim upright, exhibiting erratic movements or floating upside down.

- Increased Stress and Susceptibility to Disease: Prolonged exposure to suboptimal CO2 levels can weaken the immune system of aquatic life, making them more vulnerable to infections and diseases.

- Death: In extreme and uncorrected situations, high CO2 concentrations can be fatal to aquarium inhabitants.

Safe Handling of CO2 Cylinders

CO2 cylinders, whether they are small disposable cartridges or larger refillable tanks, are pressurized vessels and require careful handling to prevent accidents. Proper storage and connection procedures are vital for maintaining a safe environment.When handling CO2 cylinders, always adhere to the following precautions:

- Secure Storage: Store cylinders upright and secured to a wall or a sturdy stand to prevent them from tipping over. This is especially important for larger tanks.

- Avoid Extreme Temperatures: Keep cylinders away from direct sunlight, heat sources, and freezing temperatures, as extreme temperature fluctuations can affect pressure.

- Inspect for Damage: Before use, visually inspect the cylinder and valve for any signs of damage, corrosion, or leaks. Do not use a damaged cylinder.

- Proper Connection: Ensure that the regulator is securely attached to the cylinder valve according to the manufacturer’s instructions. Overtightening can damage the valve, while loose connections can lead to leaks.

- Handle with Care: Avoid dropping or roughly handling the cylinders. Treat them with the same care as any other pressurized gas container.

- Cylinder Disposal: Dispose of disposable cartridges responsibly and in accordance with local regulations. Refillable cylinders should be handled by authorized professionals.

Importance of Proper Ventilation

Adequate ventilation around the aquarium and where CO2 cylinders are stored is crucial for dissipating any potential CO2 leaks. While CO2 is heavier than air and will tend to settle, good air circulation helps to prevent dangerous concentrations from building up in enclosed spaces.Consider the following ventilation strategies:

- Open Room Ventilation: Ensure the room housing the aquarium is well-ventilated. Opening windows or using fans can significantly improve air circulation.

- Avoid Confined Spaces: Do not place CO2 cylinders or the aquarium setup in small, enclosed cabinets or rooms with poor airflow.

- Cylinder Location: If possible, store CO2 cylinders in an area with natural or mechanical ventilation, away from occupied living spaces.

- Air Exchange Rate: For dedicated aquarium rooms or areas with multiple CO2 systems, consider the air exchange rate to ensure a sufficient volume of fresh air is introduced regularly.

Monitoring Fish for Signs of CO2 Toxicity

Regularly observing your fish is the most effective way to detect early signs of CO2 toxicity. Your aquatic inhabitants will often display behavioral changes that signal distress before critical levels are reached.Pay close attention to the following indicators:

- Breathing Patterns: As mentioned earlier, rapid gill movement is a primary indicator. Compare your fish’s normal breathing rate to their current state.

- Activity Levels: A sudden decrease in activity or unusual lethargy can be a warning sign. Conversely, some fish might become hyperactive due to stress.

- Swimming Behavior: Observe how your fish are swimming. Erratic swimming, difficulty maintaining balance, or staying near the surface can all be symptoms.

- Color Changes: While not always directly related to CO2, stress can sometimes cause fish to lose color or display unusual colorations.

- Appetite: A sudden loss of appetite can indicate that fish are not feeling well, which could be due to water quality issues, including elevated CO2.

If you observe any of these signs, immediately reduce the CO2 injection rate and test your water parameters, including pH and KH, to help determine the dissolved CO2 level. A temporary increase in surface agitation can also help to off-gas excess CO2.

Optimizing CO2 Levels for Plant Growth

Achieving optimal CO2 levels is a cornerstone of a thriving high-tech planted aquarium. While it might seem like a simple matter of injecting gas, understanding the interplay between CO2, lighting, and fertilization is crucial for unlocking your plants’ full growth potential. This section will guide you through identifying and maintaining the ideal CO2 range, and how to interpret your plants’ health as indicators of CO2 balance.

Ideal CO2 Range for Planted Aquariums

The target concentration of dissolved carbon dioxide in a planted aquarium is a critical factor for robust plant photosynthesis and growth. While specific needs can vary slightly between plant species, a widely accepted range provides a safe and effective target for most high-tech setups.

For most high-tech planted aquariums, the ideal range for dissolved CO2 is between 20-40 ppm (parts per million). This range generally supports vigorous photosynthesis without posing a significant risk to fish and invertebrates. Some advanced aquarists may push this slightly higher, but it requires careful monitoring and a well-established system.

CO2 Interaction with Lighting and Fertilization

Carbon dioxide does not operate in isolation within the aquarium ecosystem. Its effectiveness and necessity are directly influenced by the intensity of your lighting and the availability of essential nutrients. This synergistic relationship is often referred to as the “Big Three” of planted tank success.

Lighting provides the energy plants need to convert CO2 and water into sugars for growth. Insufficient lighting will limit the plant’s ability to utilize available CO2, potentially leading to CO2 buildup and algae issues. Conversely, high-intensity lighting demands a commensurate supply of CO2 to prevent plants from becoming CO2-starved. Fertilization supplies the building blocks for plant tissue. Without adequate macro and micronutrients, plants cannot effectively use the CO2 provided, even with optimal lighting.

A balanced fertilization routine ensures that plants have all the necessary components to support rapid growth fueled by CO2 injection.

Strategies for Achieving Peak Plant Growth

Maximizing plant growth in a planted aquarium involves fine-tuning the CO2 injection in conjunction with other key parameters. This requires a proactive approach to monitoring and adjustment.

To achieve peak plant growth, consider the following strategies:

- Consistent CO2 Injection: Ensure your CO2 system runs for the same duration as your lights. This provides a continuous supply of carbon when plants are actively photosynthesizing.

- Gradual CO2 Introduction: When starting a new tank or adjusting levels, introduce CO2 gradually over several days. This allows plants and livestock to acclimate and helps prevent shock.

- Calibrate Monitoring Tools: Regularly calibrate your pH controller or drop checker to ensure accurate CO2 readings.

- Observe Plant Health: Your plants are the best indicators of CO2 levels. Look for signs of healthy growth, good leaf development, and consistent pearling (tiny oxygen bubbles forming on leaves).

- Adjust Based on Observation: If plants show signs of distress, or if algae becomes a problem, reassess your CO2 levels in relation to your lighting and fertilization.

Identifying and Addressing CO2 Deficiencies or Excesses

Plants themselves provide clear visual cues that can help you diagnose whether your CO2 levels are too high or too low. Learning to read these signs is essential for maintaining a healthy and balanced aquarium.

CO2 Deficiency

When CO2 levels are insufficient for the demands of your plants, especially under high lighting, several symptoms will manifest:

- Slowed or Stunted Growth: Plants will grow noticeably slower than expected.

- Small, Thin Leaves: New leaves may be smaller and thinner than normal.

- Lack of Pearling: The absence of small oxygen bubbles forming on the leaves during the photoperiod is a strong indicator of CO2 limitation.

- Algae Blooms: Ironically, CO2 deficiency can sometimes lead to algae blooms as plants are unable to outcompete algae for nutrients.

- Leaf Melting or Necrosis: In severe cases, older leaves may begin to melt or show signs of tissue death.

To address CO2 deficiency, gradually increase the CO2 injection rate. Monitor your drop checker or pH meter and observe plant health over the next few days. Ensure your CO2 system is running for the full duration of your lighting period.

CO2 Excess

An excessive amount of dissolved CO2 can be detrimental to both plants and aquatic life. Symptoms of CO2 excess include:

- Rapid Breathing in Fish: Fish may exhibit rapid gill movements, gasping at the surface, or swimming erratically. This is a critical sign of distress.

- pH Crash: A sudden and significant drop in pH can occur as CO2 levels rise.

- Plant Tissue Damage: While less common, extremely high CO2 levels can sometimes lead to tissue damage in sensitive plants.

- Algae Outbreaks: Paradoxically, while CO2 is vital for plant growth, an imbalance can still contribute to algae issues if other factors are not optimized.

To address CO2 excess, immediately reduce the CO2 injection rate. Turn off the CO2 supply if necessary and ensure adequate surface agitation to help gas exchange. Monitor your fish closely for signs of distress. It is advisable to reduce CO2 injection until fish behavior returns to normal, then reintroduce CO2 at a lower rate, allowing for gradual acclimation.

Final Conclusion

Successfully setting up and maintaining a CO2 system is a cornerstone of high-tech planted aquascaping, transforming ordinary tanks into breathtaking underwater landscapes. By carefully selecting your equipment, ensuring secure connections, and diligently monitoring your system, you are well on your way to cultivating lush, vibrant aquatic plants. This comprehensive guide has equipped you with the knowledge to overcome challenges, optimize CO2 levels, and ultimately achieve the aquarium of your dreams, fostering a healthy and visually stunning environment for both your plants and aquatic inhabitants.