Embarking on the journey of How to Reseal a Leaking Aquarium Seam is a crucial undertaking for any aquarium enthusiast. A compromised seam not only threatens the integrity of your aquatic habitat but also poses potential risks to your cherished inhabitants and surrounding environment. This comprehensive guide is meticulously crafted to equip you with the knowledge and practical steps necessary to confidently address and rectify a leaking aquarium seam, ensuring the long-term health and safety of your underwater world.

Understanding the root causes of seam leaks, from material degradation to improper initial sealing, is the first step toward effective repair. We will delve into the various types of sealants available, their unique properties, and the tell-tale signs that indicate a failing seam. By mastering these foundational elements, you’ll be well-prepared to tackle the resealing process with precision and care.

Understanding Aquarium Seam Leaks

A leaking aquarium seam is a common and potentially distressing issue for aquarium enthusiasts. Fortunately, with a proper understanding of the causes, sealant types, risks, and signs, most leaks can be effectively addressed. This section will equip you with the foundational knowledge to identify and comprehend the nature of aquarium seam leaks.Understanding the intricacies of your aquarium’s construction and the materials used is paramount to preventing and rectifying leaks.

By delving into the common culprits, the properties of different sealants, the inherent risks, and the tell-tale symptoms, you can approach the repair process with confidence and ensure the long-term health of your aquatic environment.

Common Causes of Aquarium Seam Leaks

Aquarium seams, typically formed by silicone sealant, are the critical points where glass panels are joined. Over time, these seams can degrade or fail due to a variety of factors, leading to leaks.The primary reasons for seam failure include:

- Age and Degradation of Sealant: Silicone sealant has a finite lifespan. Exposure to water, UV light, and cleaning chemicals can cause it to break down, lose its adhesion, and become brittle, eventually leading to cracks or separation.

- Physical Stress and Impact: Dropping the aquarium, bumping it against hard surfaces, or even significant temperature fluctuations can put stress on the seams, potentially causing them to crack or detach.

- Improper Initial Sealing: If the aquarium was not sealed correctly during manufacturing or a previous repair, there might be air bubbles, gaps, or insufficient adhesion from the outset, making the seam prone to leaks.

- Corrosion or Contamination: In some cases, mineral deposits or other contaminants can build up along the seam, weakening the bond between the glass and the sealant over time.

- Manufacturing Defects: While less common, manufacturing flaws in the glass or the sealing process can lead to premature seam failure.

Types of Aquarium Sealants and Their Properties

The integrity of an aquarium’s seams relies heavily on the quality and type of sealant used. Aquarium-specific silicone sealants are designed to be non-toxic to aquatic life and to withstand constant submersion in water.Key properties and types of sealants include:

- 100% Silicone Sealant: This is the standard for aquarium construction and repair. It is inert, waterproof, and flexible, providing a strong and durable bond. It’s crucial to use a sealant that is specifically labeled as aquarium-safe, as some general-purpose silicones contain mildew inhibitors or other additives that are toxic to fish and invertebrates.

- Curing Time: Aquarium silicone requires a significant curing period, typically 24-48 hours for initial set and up to 7 days for a full cure, depending on thickness and humidity. During this time, the sealant releases acetic acid (which causes the vinegar-like smell), and it’s essential to ensure adequate ventilation and that the aquarium is not filled with water.

- Adhesion: The ability of the sealant to bond strongly to glass is critical. Proper surface preparation, including thorough cleaning and drying, is essential for optimal adhesion.

- Flexibility: A degree of flexibility is necessary to accommodate minor movements and temperature changes without cracking.

It is important to note that once silicone has cured, it forms a rubbery, durable barrier. It should not be confused with other adhesives like epoxy or caulk, which may not be suitable or safe for long-term aquarium use.

Potential Risks Associated with a Leaking Aquarium Seam

A leaking aquarium seam poses several significant risks, extending beyond the immediate inconvenience of water loss. These risks can impact not only the aquarium inhabitants but also the surrounding environment and property.The potential dangers include:

- Flooding and Water Damage: The most apparent risk is water escaping the aquarium, which can lead to significant damage to flooring, furniture, carpets, and electrical systems. In severe cases, this can result in costly repairs and even structural damage to a home.

- Stress and Harm to Aquatic Life: A sudden drop in water level due to a leak can cause immense stress to fish and other aquatic organisms. This stress can weaken their immune systems, making them susceptible to diseases, and in extreme cases, can be fatal. Rapid changes in water parameters also pose a threat.

- Electrical Hazards: Water leaking from an aquarium can come into contact with electrical equipment, such as lights, filters, and heaters, creating a serious risk of electric shock and fire.

- Loss of Livestock: If a leak is not detected and addressed promptly, the aquarium can empty to a critical level, leading to the death of all its inhabitants.

- Compromised Structural Integrity: A failing seam can indicate a larger problem with the aquarium’s construction, potentially leading to a catastrophic failure where the entire aquarium collapses.

Typical Signs and Symptoms of a Failing Aquarium Seam

Early detection of a failing aquarium seam is crucial for preventing major issues. Recognizing the subtle and not-so-subtle signs can allow for timely intervention and repair.Common indicators of a compromised seam include:

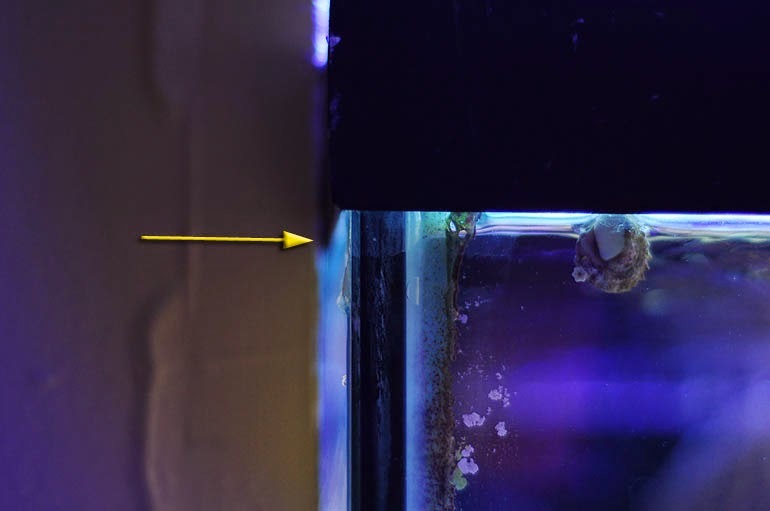

- Visible Water Trails: Look for dried water marks or streaks running down the outside of the aquarium, especially near the bottom corners or along the base of the seams. These are often the first and most obvious signs of a slow leak.

- Dampness on the Exterior: The outside surface of the glass near a leaking seam may feel damp or cool to the touch, even if no visible water trails are present.

- Mold or Mildew Growth: In older aquariums, moisture escaping a seam can encourage the growth of mold or mildew on the exterior surfaces or the stand beneath the aquarium.

- Bubbles in the Sealant: Inspect the silicone seams closely for any small bubbles trapped within the sealant. These can indicate a loss of adhesion or a weak point where water can begin to seep through.

- Cracks or Gaps in the Sealant: Any visible cracks, tears, or separations in the silicone sealant are a clear indication of a failing seam. This might appear as a hairline crack or a more significant gap.

- Lowered Water Level: If you notice the water level consistently dropping faster than can be accounted for by evaporation, a leak should be suspected. Regularly check your water level against a marked point on the glass.

- Discoloration or Deterioration of Sealant: Over time, silicone can change color, becoming cloudy, brittle, or even peeling away from the glass, signaling its deterioration.

Safety and Preparation for Resealing

Before embarking on the task of resealing a leaking aquarium seam, prioritizing safety and thorough preparation is paramount. This meticulous approach ensures not only your well-being but also the longevity and integrity of the repair. A well-prepared environment and the right tools will make the process smoother and more effective.A comprehensive understanding of the necessary tools and materials, alongside stringent safety protocols, will equip you to handle the resealing process with confidence.

This section will guide you through these crucial preparatory steps, ensuring you are ready to tackle the repair effectively and safely.

Necessary Tools and Materials for Resealing

Gathering the appropriate tools and materials before you begin is essential for a successful and efficient resealing process. Having everything readily accessible will prevent interruptions and ensure a professional finish.The following list Artikels the key items you will need:

- Aquarium-Safe Silicone Sealant: Ensure the sealant is specifically designed for aquariums, as standard household silicones can be toxic to aquatic life. Look for products that are 100% silicone and free of mold or mildew inhibitors.

- Razor Blade Scraper or Putty Knife: For carefully removing old sealant. A dedicated aquarium scraper with a replaceable blade is ideal.

- Gloves: To protect your hands from sealant and cleaning agents. Nitrile or latex gloves are suitable.

- Safety Glasses: To protect your eyes from debris and sealant splashes.

- Paper Towels or Rags: For cleaning and drying.

- Rubbing Alcohol (Isopropyl Alcohol): A high percentage (90% or above) is best for thoroughly cleaning and degreasing the seam.

- Masking Tape or Painter’s Tape: To create clean, straight lines and protect the glass from excess sealant.

- Caulking Gun: For applying the silicone sealant smoothly and evenly.

- Small Container or Tray: To hold scraped sealant and cleaning materials.

- Bucket: For disposing of waste materials and for holding water if needed.

- Optional: Plastic Spatula or Silicone Smoothing Tool: For achieving a perfectly smooth bead of sealant.

Essential Safety Precautions

Working with tools and chemicals requires a mindful approach to safety. Adhering to these precautions will help prevent injuries and ensure a safe working environment for both you and your aquatic inhabitants.It is imperative to take the following safety measures before commencing any work on the aquarium:

- Ventilation: Ensure the area where you are working is well-ventilated. Silicone sealants release fumes during application and curing, which can be harmful if inhaled in enclosed spaces. Open windows and doors if possible.

- Eye Protection: Always wear safety glasses to shield your eyes from stray sealant, debris, or cleaning solutions.

- Skin Protection: Wear gloves to prevent direct contact with silicone sealant and cleaning agents, which can irritate the skin.

- Sharp Tools: Exercise extreme caution when using razor blades or scrapers to avoid cuts. Always scrape away from your body and keep fingers clear of the blade’s path.

- Aquatic Life Safety: If you are working on a filled or partially filled aquarium, ensure that all fish and invertebrates are safely relocated to a temporary, stable environment before you begin. Even trace amounts of uncured sealant can be toxic.

Draining and Preparing the Aquarium

Properly draining and preparing the aquarium is a critical step that ensures a clean and accessible surface for resealing. This process minimizes stress on your aquatic life and maximizes the adhesion of the new sealant.The following steps detail the safe and effective draining and preparation of your aquarium:

- Relocate Aquatic Life: As mentioned in the safety precautions, the first and most important step is to carefully and safely move all fish, invertebrates, and live plants to a separate, secure holding tank or container filled with conditioned aquarium water. Ensure the temporary environment is stable in terms of temperature and water parameters.

- Drain the Water: Use a gravel vacuum or siphon to drain the aquarium water into a clean bucket or suitable container. Aim to drain enough water to expose the entire seam you need to repair, typically leaving only a few inches of water at the bottom if the leak is low, or draining it completely if the leak is higher up. Complete draining is often preferred for thorough cleaning and drying.

- Remove Decorations and Substrate (if necessary): If the leak is extensive or the seam is difficult to access, you may need to remove decorations, rocks, and even a portion of the substrate to gain full access to the affected area. Place these items in a separate container with some of the drained aquarium water.

- Secure the Glass Panels: If the aquarium is completely drained, especially larger tanks, consider using temporary supports or bracing to ensure the glass panels remain stable and do not shift while the sealant is being removed and reapplied.

Cleaning and Drying Aquarium Seams

A clean and completely dry seam is fundamental for the new silicone sealant to adhere properly and form a watertight bond. Any residual dirt, old sealant, or moisture will compromise the integrity of the repair.Follow these steps for thorough cleaning and drying of the aquarium seams:

- Remove Old Sealant: Using your razor blade scraper or putty knife, carefully and patiently scrape away all the old, degraded silicone sealant from the inside and outside of the seam. Work slowly and avoid scratching the glass. It is often easier to score the old sealant first with the blade, then lift it away.

- Degrease the Seam: Once the bulk of the old sealant is removed, apply rubbing alcohol to a clean paper towel or rag. Thoroughly wipe down the entire seam area on both the inside and outside of the aquarium. This step is crucial for removing any grease, oils, or remaining residue that could prevent the new sealant from bonding.

- Wipe Down with Clean Water: After degreasing, use a clean, damp paper towel or rag (rinsed with plain water) to wipe away any residual alcohol.

- Dry Thoroughly: This is a critical step. Use dry paper towels or a lint-free cloth to meticulously dry the seam area. Ensure there is absolutely no moisture present. You may need to let the aquarium air dry for a significant period, especially in humid conditions. Using a fan directed at the seam can speed up the drying process.

The glass should feel completely dry and smooth to the touch.

Step-by-Step Resealing Procedure

Successfully resealing a leaking aquarium seam involves a meticulous process of removing the old, compromised sealant and applying a new, robust barrier. This guide will walk you through each critical step, ensuring a watertight repair that will restore your aquarium’s integrity. Precision and patience are key to achieving professional-grade results.

Removing Old, Failing Sealant

The first and arguably most crucial step is the thorough removal of all old, degraded silicone. Any residual sealant can compromise the adhesion of the new silicone, leading to future leaks. A systematic approach ensures a clean surface for the new application.

The following tools are essential for effective old sealant removal:

- Razor Blade or Utility Knife: For carefully scraping away larger sections of silicone. It’s vital to hold the blade at a shallow angle to avoid scratching the glass.

- Plastic Scraper or Putty Knife: A safer alternative for initial removal, especially on acrylic tanks, to prevent scratching.

- Silicone Remover Solvent (Aquarium-Safe): Specialized solvents can help soften stubborn silicone residue, making it easier to scrape away. Always ensure the product is explicitly labeled as aquarium-safe.

- Lint-Free Cloths or Paper Towels: For wiping away loosened silicone and cleaning the area.

- Gloves: To protect your hands from sharp tools and any cleaning solvents.

The process for removing old sealant typically involves:

- Initial Scraping: Begin by carefully using a razor blade or plastic scraper to lift and peel away as much of the old silicone as possible from both the inside and outside of the seam. Work methodically along the entire length of the seam.

- Solvent Application (if necessary): If stubborn residue remains, apply a small amount of aquarium-safe silicone remover to a cloth and dab it onto the affected areas. Allow it to sit for the time recommended by the product manufacturer.

- Further Scraping and Wiping: Once the silicone has softened, continue scraping with your chosen tool. Frequently wipe away the loosened silicone with lint-free cloths.

- Detailing Edges: Pay close attention to the edges where the silicone meets the glass. Use a sharp blade or a specialized scraping tool to ensure no remnants are left behind.

- Final Cleaning: After all visible silicone is removed, clean the entire seam area thoroughly with rubbing alcohol (isopropyl alcohol, 70% or higher) on a lint-free cloth. This removes any remaining residue, oils, or contaminants, ensuring optimal adhesion for the new silicone. Allow the area to dry completely.

Applying New Aquarium-Safe Silicone Sealant

Applying new silicone requires a steady hand and a methodical approach to create a strong, watertight seal. Using the correct type of silicone and applying it evenly is paramount.

For successful application, gather the following:

- Aquarium-Safe Silicone Sealant: Ensure it is 100% silicone and specifically formulated for aquarium use. Common brands include GE Silicone I (clear) or specific aquarium silicone products. Avoid any products labeled “mildew resistant” or containing fungicides, as these are toxic to aquatic life.

- Caulking Gun: A standard caulking gun will be needed to dispense the silicone.

- Applicator Tip: Most silicone tubes come with a cone-shaped tip that can be cut to the desired bead size.

- Masking Tape (Painter’s Tape): To create clean lines and protect surrounding areas.

- Gloves: To keep your hands clean.

The application process involves these key steps:

- Prepare the Tube: Cut the tip of the silicone tube at a 45-degree angle to achieve the desired bead width. Start with a smaller opening; you can always cut more off if needed. Puncture the inner seal of the tube if it has one.

- Apply Masking Tape: For a very clean finish, apply masking tape to the glass on either side of the seam, creating a guide for your silicone bead. The gap between the tape should be the width you want your final silicone bead to be.

- Dispense Silicone: Load the silicone tube into the caulking gun. Apply steady, even pressure to the trigger while moving the gun smoothly along the seam. Aim to lay down a continuous, unbroken bead of silicone that fills the gap completely. Ensure the silicone is pushed into the seam rather than just sitting on top.

- Work in Sections: For larger aquariums, it may be easier to work in manageable sections rather than trying to do the entire seam at once.

Creating a Smooth and Consistent Bead

A smooth, consistent bead of silicone is not only aesthetically pleasing but also contributes to the seal’s integrity by eliminating potential weak points or air pockets.

The following techniques are effective for achieving a professional finish:

- Tooling with a Finger: After applying the silicone, immediately use a gloved finger dipped in a solution of mild dish soap and water. Run your finger along the bead of silicone, pressing it gently into the seam and smoothing it to a consistent profile. This action pushes the silicone into any crevices and creates a concave surface.

- Using a Silicone Tooling Stick or Spatula: Specialized tools or even a plastic spatula can be used to achieve a very uniform bead. These tools are designed to create a specific concave or flat profile.

- Wiping Excess: Have damp paper towels or cloths ready to wipe away any excess silicone that squeezes out from under your tooling tool.

It is important to work quickly once the silicone is applied, as it begins to skin over relatively fast. If you are not satisfied with a section, you can carefully remove it and reapply before it cures.

Tooling and Finishing the Freshly Applied Sealant

The tooling process is critical for ensuring the silicone adheres properly and forms a smooth, watertight barrier. It’s about pressing the silicone into the seam and removing excess material.

Best practices for tooling and finishing include:

- Immediate Tooling: Begin tooling within minutes of applying the silicone. The longer you wait, the more difficult it will be to create a smooth finish.

- Consistent Pressure: Apply consistent pressure with your chosen tooling method (finger, tool) to ensure the silicone is pressed firmly into the seam and to create a uniform shape.

- Angle of Tooling: For a concave bead, which is ideal for aquarium seams, hold your finger or tool at a slight angle to create a smooth, curved surface that funnels water away from the seam.

- Cleaning Excess: As you tool, use a damp cloth or paper towel to wipe away any excess silicone that accumulates on your finger or tool. This prevents it from sticking to unintended areas.

- Removing Masking Tape: If you used masking tape, carefully peel it away immediately after tooling. Pull the tape away at an angle, pulling it back on itself to avoid disturbing the fresh silicone bead.

- Final Inspection: Once the tape is removed, inspect the seam for any missed spots or imperfections. Small touch-ups can sometimes be made with a small amount of silicone applied with a fine-tipped tool, but it’s best to avoid excessive manipulation.

Curing Process Requirements for Different Types of Sealants

The curing time for aquarium silicone is a critical period during which the sealant hardens and becomes fully functional. Adhering to the manufacturer’s recommended curing times is essential for a safe and durable repair.

Curing requirements vary based on the silicone formulation:

- Standard Aquarium Silicone (Acetoxy Cure): This is the most common type for aquariums. It typically requires a minimum of 24 to 48 hours to cure sufficiently to be considered watertight. However, for optimal safety and to ensure complete off-gassing of acetic acid (which can be harmful to fish), it is highly recommended to allow a full 7 days of curing in a well-ventilated area before filling the aquarium.

- Neutral Cure Silicone: While less common for DIY aquarium resealing, neutral cure silicones generally have faster curing times and less odor. They may still require a minimum of 24-72 hours, but always refer to the product’s specific instructions.

Key considerations for the curing process include:

- Ventilation: Ensure the aquarium is in a well-ventilated area during the curing process. This helps to dissipate any fumes and ensures the silicone cures properly.

- Temperature and Humidity: Curing times can be affected by ambient temperature and humidity. Higher temperatures and lower humidity generally lead to faster curing, while colder, more humid conditions will slow down the process.

- No Stress on the Seam: During the curing period, do not place any weight or stress on the resealed seam. The aquarium should remain empty and undisturbed.

- Testing for Full Cure: While visual inspection can indicate that the surface has skinned over, it doesn’t mean the silicone is fully cured throughout. The 7-day recommendation for standard aquarium silicone is a conservative but safe approach.

For standard aquarium-safe silicone, a minimum of 24-48 hours is required for initial curing, but a full 7 days is strongly advised before introducing water and aquatic life to ensure complete off-gassing and maximum bond strength.

Curing and Refilling the Aquarium

Proper curing of aquarium sealant is a critical step that ensures the long-term integrity of your resealed aquarium. Rushing this process can lead to premature leaks and the need for further repairs. This section will guide you through understanding curing times, verifying complete curing, and the careful process of refilling your aquarium.The curing process for silicone sealant is a chemical reaction that transforms the liquid sealant into a solid, watertight barrier.

This reaction is influenced by factors such as temperature, humidity, and the thickness of the sealant bead. Adhering to recommended curing times is paramount for achieving a durable and reliable seal.

Sealant Curing Times and Importance

Aquarium-specific silicone sealants are formulated to be inert and safe for aquatic life once fully cured. However, before this point, they can release volatile organic compounds (VOCs) that are harmful to fish and invertebrates. Therefore, allowing adequate curing time is not just about structural integrity but also about the health of your aquarium’s inhabitants.The curing process typically occurs in two stages: surface curing and full curing.

Surface curing happens relatively quickly, where a skin forms on the outside of the sealant, making it tack-free. Full curing, however, penetrates the entire depth of the sealant bead and can take significantly longer.

Always consult the manufacturer’s instructions for the specific silicone sealant you are using, as curing times can vary between brands and formulations.

For most standard aquarium silicones, a minimum of 24 to 48 hours is recommended for surface curing, and a full 7 days (168 hours) is often advised for complete curing, especially for thicker beads or in cooler, less humid conditions.

Checking for Complete Sealant Curing

Before refilling your aquarium, it is essential to confirm that the sealant has fully cured. This can be done through a few simple checks.

- Tack-Free Test: Gently touch the sealant bead with a gloved finger. If it feels firm and does not transfer to your glove or leave an indentation, the surface has cured.

- Flexibility Test: Carefully try to flex the glass panels slightly where the sealant is applied. A fully cured bead will be firm but still possess a slight, controlled flexibility. If it feels brittle or overly soft, it requires more curing time.

- Smell Test: A strong, chemical odor indicates that curing is still in progress. A fully cured silicone should have a minimal or no discernible smell.

If you are unsure, it is always better to err on the side of caution and allow an additional day or two for curing.

Refilling the Aquarium

Once you are confident that the sealant has fully cured, you can proceed with refilling your aquarium. This process should be done carefully to avoid stressing the newly sealed seams.

- Clean the Aquarium: Before adding water, thoroughly rinse the inside of the aquarium with clean, dechlorinated water to remove any dust or debris from the curing process.

- Place Substrate and Decorations: Carefully add your substrate and any decorations. Ensure that heavy items are not placed directly on the bottom seam, which could put undue pressure on the fresh sealant.

- Slow Water Introduction: Begin filling the aquarium slowly with dechlorinated water. Avoid using a strong stream of water that could directly hit and potentially erode the fresh sealant. A good method is to pour water onto a plate or a clean piece of plastic placed on the substrate to diffuse the flow.

- Fill Gradually: Fill the aquarium to your desired level, continuing to monitor the flow of water to ensure it is gentle.

Initial Leak Testing After Refilling

After the aquarium is filled, it is crucial to perform an initial leak test to confirm the success of your resealing efforts. This is a critical step before introducing livestock.

- Observation Period: Allow the aquarium to sit for at least 24 hours after refilling. During this time, meticulously inspect all seams, both inside and outside the aquarium, for any signs of moisture, drips, or water accumulation. Pay close attention to the areas you resealed.

- Wipe Down Test: Periodically, use a dry paper towel or cloth to wipe down the exterior of the seams. If any moisture appears on the towel, it indicates a leak.

- Water Level Check: Monitor the water level in the aquarium. A significant drop that cannot be attributed to evaporation could signal a slow leak.

If you detect any leaks, drain the aquarium immediately and repeat the resealing process, paying close attention to the specific area where the leak occurred. Ensure the area is completely dry and free of old silicone before reapplying new sealant.

Advanced Techniques and Troubleshooting

While the core process of resealing an aquarium seam is consistent, certain situations and challenges require specialized approaches. This section delves into advanced techniques for different seam types, provides solutions for common problems, and Artikels preventative measures to ensure the long-term integrity of your aquarium.

Internal Versus External Seam Resealing Methods

The approach to resealing an aquarium seam can differ significantly depending on whether the leak is originating from an internal or external seam. Understanding these distinctions is crucial for effective repair.

Internal seams, typically found on the inside corners of the aquarium, are generally more straightforward to address. The silicone is applied to the inside, creating a water-tight barrier. For external seams, which are less common in modern aquariums but may be found on older models or custom builds, the approach might involve reinforcing or re-applying silicone on the exterior, often requiring the aquarium to be emptied and carefully handled.

Internal Seam Resealing:

- Access: Internal seams are readily accessible when the aquarium is filled or partially filled, allowing for a more immediate repair.

- Silicone Application: A bead of aquarium-safe silicone is applied directly into the existing seam or over a compromised area.

- Tooling: A tooling tool or a gloved finger is used to smooth the silicone, ensuring a complete seal and a clean finish.

- Curing: Sufficient curing time is essential, typically 24-48 hours, before refilling the aquarium.

External Seam Resealing:

- Draining: External seam repairs almost always necessitate complete draining of the aquarium to prevent water ingress during the repair process.

- Cleaning: Thorough cleaning and drying of the exterior seam are paramount. Any residue or moisture will compromise adhesion.

- Silicone Application: Silicone is applied to the exterior joint, creating a secondary seal. This is often done in conjunction with internal inspection and potential internal resealing.

- Support: For larger aquariums, temporary bracing or support might be needed during the drying and curing process to maintain the integrity of the glass panels.

Troubleshooting Common Resealing Issues

Even with careful preparation, unforeseen problems can arise during the resealing process. Having a troubleshooting guide can help you address these issues effectively and ensure a successful repair.

It’s important to anticipate potential challenges and have solutions ready. This proactive approach can save time and prevent the need for more extensive repairs later on.

| Issue | Possible Cause | Solution |

|---|---|---|

| Silicone not adhering | Inadequate cleaning or drying of the seam; presence of dust, grease, or old silicone residue. | Thoroughly clean the seam with rubbing alcohol and allow it to dry completely. If old silicone is present, carefully scrape it away using a razor blade. |

| Air bubbles trapped in silicone | Improper tooling of the silicone bead; silicone applied too quickly. | Tool the silicone slowly and deliberately, ensuring even pressure. If bubbles are present after initial tooling, you may need to carefully remove the affected area and reapply silicone. |

| Silicone shrinking or pulling away | Using non-aquarium-safe silicone; insufficient curing time before exposure to water. | Always use 100% aquarium-safe silicone. Ensure the silicone is fully cured according to the manufacturer’s instructions (typically 24-48 hours in a well-ventilated area) before refilling. |

| Persistent minor leaks after resealing | Missed small cracks or gaps; insufficient silicone applied. | Carefully inspect the resealed seam under good lighting. If a small gap is found, a second, thin bead of silicone may be applied and tooled. For larger issues, the entire seam may need to be redone. |

| Uneven or messy silicone application | Lack of practice; improper tooling technique. | Practice on scrap glass or a piece of cardboard before working on the aquarium. Experiment with different tooling methods to achieve a smooth, consistent bead. |

Resealing Curved or Unusually Shaped Aquarium Seams

Aquariums with curved fronts or other non-standard shapes present unique challenges for resealing. The curvature requires a different approach to ensure a uniform and effective seal.

Working with curved glass demands patience and a slightly modified technique to achieve the same level of watertightness as with straight seams. The key is to maintain consistent contact and pressure along the entire curve.

- Preparation: Thorough cleaning and drying are even more critical for curved seams, as any unevenness can be amplified by the curve.

- Silicone Application: Apply a continuous bead of silicone, moving slowly and steadily along the curve. Avoid stopping and starting if possible.

- Tooling: For curved surfaces, a flexible tooling tool or a rounded object (like the back of a spoon) can be more effective than a rigid tool. Gently follow the curve of the glass, applying even pressure. Some hobbyists find using a wet finger (with a glove) to be effective, as it allows the silicone to conform to the curve.

- Support and Drying: Ensure the aquarium is placed on a level surface and that there are no stresses on the curved panels during the curing process.

Preventative Maintenance Strategies for Future Seam Integrity

The best way to avoid seam leaks is through diligent preventative maintenance. Regular checks and proper care can significantly extend the life of your aquarium’s seals.

Proactive care is always more efficient than reactive repair. By incorporating these strategies into your aquarium routine, you can minimize the risk of future leaks and maintain a healthy environment for your aquatic inhabitants.

- Regular Inspections: Periodically inspect all aquarium seams, both internally and externally, for any signs of cracking, separation, or degradation of the silicone. Look for cloudy areas or small gaps.

- Avoid Harsh Chemicals: Never use abrasive cleaners or harsh chemicals inside or outside the aquarium, as they can degrade the silicone over time.

- Temperature Stability: Extreme temperature fluctuations can stress the glass and silicone. Maintain a stable water temperature.

- Proper Placement: Ensure the aquarium is placed on a sturdy, level stand. Uneven weight distribution can put undue stress on the seams.

- Gentle Cleaning: When cleaning the aquarium, avoid excessive scraping or poking at the silicone seams. Use appropriate aquarium cleaning tools.

- Controlled Filling and Draining: When performing water changes, avoid sudden, forceful filling or draining that could create pressure surges against the seams.

- Monitor Water Parameters: While not directly related to silicone, maintaining stable water parameters is crucial for the overall health of the aquarium, which indirectly supports the longevity of all its components.

Visualizing the Process

Understanding the visual cues throughout the resealing process is paramount for achieving a professional and leak-free result. This section will guide you through the key stages, from the meticulous preparation of the seam to the final cured sealant bead, ensuring you can confidently identify correct techniques and potential issues.

Preparing the Seam for Resealing

The visual transformation of a damaged seam into a pristine surface ready for new sealant is a critical first step. This involves the careful removal of old silicone and thorough cleaning to ensure optimal adhesion for the new material. Imagine a dirty, cracked line where water has begun to seep; our goal is to meticulously erase this evidence of failure and prepare a perfectly clean canvas.The removal of old silicone requires a keen eye for detail.

You will see the old sealant, often discolored, cracked, or peeling away from the glass. Using a sharp, flat blade, such as a razor scraper or a specialized aquarium silicone removal tool, you will carefully slice along the edge of the old silicone, working it away from the glass. The goal is to remove all traces of the old material without scratching the glass itself.

This process will leave behind a clean glass surface, free from any lingering silicone residue. Following the physical removal, a thorough cleaning is essential. Visualize wiping down the exposed glass edges with a lint-free cloth dampened with isopropyl alcohol. This removes any remaining dust, debris, or oily residues that could compromise the new sealant’s bond. The glass should appear clean, clear, and completely dry before proceeding.

Applying the Sealant

Applying the new aquarium-grade silicone sealant is where precision and a steady hand are visually rewarded. The aim is to create a uniform, continuous bead that effectively bridges the gap and forms a watertight barrier. Observe the nozzle of the silicone tube as you begin. It should be cut at an angle to create a bead of the desired width, typically matching the original seam’s thickness.As you apply the sealant, imagine drawing a smooth, unbroken line along the entire length of the seam.

The pressure on the trigger of the caulking gun should be consistent, ensuring a steady flow of silicone. The bead should appear slightly raised, forming a convex surface that will later be smoothed. Avoid stopping and starting abruptly, which can create weak points or unevenness. Overlapping slightly at the start and end of each section can help ensure a continuous seal.

The visual objective is a single, uninterrupted bead of silicone that completely covers the joint between the glass panels.

The Ideal Finished Sealant Bead

Once applied, the sealant bead should present a specific visual profile that indicates a successful application. This is the final, smoothed bead that will be the primary defense against leaks. The ideal finished bead is characterized by its smooth, consistent appearance and its firm adhesion to both glass surfaces.Visually, the smoothed bead should be slightly concave or have a gentle, uniform curve, pressing firmly into the corner of the aquarium seam.

It should not have any gaps, air bubbles, or voids. The edges of the bead should taper smoothly onto the glass, creating a clean transition without excess silicone smeared onto the surrounding glass. The color should be uniform, and the texture should be smooth and free of ridges or imperfections. This visually appealing and structurally sound bead signifies a job well done, ready for the curing process.

Visual Cues During Curing

The curing process is a critical phase where the liquid silicone transforms into a solid, flexible, and watertight seal. Observing the sealant during this period provides visual confirmation of its hardening. While the primary indicator is time, certain visual cues can offer reassurance.Initially, the applied sealant will appear wet and glossy. As it begins to cure, you will notice a subtle change in its surface texture.

The glossy sheen will start to diminish, and the bead will develop a more matte finish. You may also observe a slight shrinkage or pulling away from the edges of the nozzle application point as the curing progresses. The sealant will become less tacky to the touch, transitioning from a sticky surface to a firm, rubbery texture. A fully cured bead will be firm throughout its depth, with no soft or uncured areas remaining.

If you were to gently press the bead, it should feel solid and resilient, indicating that the chemical cross-linking process is complete and the sealant is ready to withstand the pressure of water.

Material Selection and Alternatives

Choosing the right materials is paramount for a successful and long-lasting aquarium resealing project. Not all sealants are created equal, and understanding their properties, along with the tools used for application and removal, will significantly impact the safety and integrity of your aquarium. This section delves into the critical aspects of material selection and explores various alternatives.

Aquarium-Safe Silicone Sealants

The primary material for resealing an aquarium is aquarium-safe silicone sealant. These sealants are specifically formulated to be non-toxic to aquatic life once fully cured. It’s crucial to distinguish between general-purpose silicone and aquarium-specific silicone, as the former can leach harmful chemicals into the water.

- 100% Silicone Sealant: This is the standard for aquarium resealing. It offers excellent adhesion, flexibility, and water resistance. Ensure it is explicitly labeled “aquarium safe” or “100% silicone, no additives.”

- Mildew-Resistant Silicone: While seemingly beneficial, mildew-resistant silicones often contain fungicides that are toxic to fish. It is best to avoid these for aquarium applications.

- Acetoxy vs. Neutral Cure Silicone: Acetoxy cure silicones release acetic acid (vinegar smell) during curing, which can be corrosive and harmful to some aquarium inhabitants. Neutral cure silicones release alcohol or oxime and are generally preferred for aquarium use due to their less aggressive curing process.

When selecting a sealant, always look for the “100% silicone” and “aquarium safe” labels. Avoid products that mention “mildew resistance,” “anti-fungal,” or “anti-bacterial” properties, as these often indicate the presence of toxic additives.

Sealant Removal Tools

Efficiently and safely removing old silicone is a critical step. Using the wrong tools can scratch the glass or fail to remove the sealant completely, compromising the new seal.

Various tools can be employed for sealant removal, each with its advantages and limitations. The goal is to scrape away the old silicone without damaging the aquarium glass or frame.

- Razor Blades/Scrapers: A sharp, single-edge razor blade or a dedicated glass scraper is highly effective for cutting through and peeling away silicone. It’s essential to hold the blade at a low angle to the glass to avoid scratching. For plastic tanks, a plastic scraper is a safer alternative.

- Putty Knives: A thin, flexible putty knife can be useful for prying up larger sections of silicone once it has been loosened by a blade. Metal putty knives should be used with caution on glass to prevent scratches.

- Specialized Aquarium Silicone Removal Tools: Several brands offer plastic tools specifically designed for aquarium silicone removal. These often have curved edges to match the aquarium corners and are made from materials less likely to scratch glass.

- Wire Brushes: Generally not recommended for glass aquariums as they can cause significant scratching. They might be considered for very stubborn residue on frames if made of durable material, but extreme caution is advised.

The most effective approach often involves a combination of tools. Start with a sharp razor blade to cut the silicone, then use a putty knife or specialized tool to lift and scrape away the loosened material.

Temporary Leak Patching Methods and Limitations

In some urgent situations, a temporary patch might be necessary to prevent further water loss before a permanent reseal can be performed. However, these methods are not a substitute for proper resealing and should be considered short-term solutions.

Temporary fixes are useful for emergency situations but come with significant limitations and are not designed for long-term submersion or structural integrity.

- Waterproof Tape: Heavy-duty, waterproof tape (e.g., Gorilla Tape, marine-grade tape) can be applied to the exterior of the leak. This is a very temporary solution, and the adhesive may degrade over time, especially with constant moisture and temperature fluctuations. It’s crucial to ensure the tape is applied to a clean, dry surface.

- Epoxy Putty: Certain waterproof epoxy putties can be molded and applied to the exterior of the leak. While stronger than tape, it’s still a temporary fix. The putty must be specifically rated for underwater use and should be applied to a clean, dry surface. The long-term adhesion and potential for leaching into the water are concerns.

- Clamps and Rubber: For minor leaks along a seam, a rubber gasket or piece of thick rubber can be placed over the leak area on the exterior, and then secured tightly with adjustable clamps. This method relies on mechanical pressure to stop the flow and is highly susceptible to failure if the clamps loosen or the rubber degrades.

It is vital to understand that these temporary methods are not reliable for extended periods. They can fail without warning, leading to significant water loss or even a complete tank failure. They should only be used as a stopgap measure until a proper resealing can be completed.

Comparison of Sealant Brands: Curing Times and Durability

The choice of sealant brand can influence the time it takes to get your aquarium back up and running and the longevity of the seal. While most aquarium-safe silicones share similar properties, slight variations in formulation can affect their performance.

When comparing sealant brands, two key factors to consider are curing time and long-term durability. These metrics help determine how quickly you can refill your aquarium and how long you can expect the seal to last.

| Brand Example | Curing Time (Surface Dry) | Curing Time (Full Cure) | Durability | Notes |

|---|---|---|---|---|

| API Aquarium Sealant | 1-2 hours | 24-48 hours | Excellent, specifically formulated for aquariums. | Widely available, trusted brand. |

| Marineland Aquarium Sealant | 1-2 hours | 24-48 hours | Excellent, designed for underwater applications. | Good adhesion and flexibility. |

| D-D Aquariums Silicone Sealant | 1-2 hours | 24-48 hours | Excellent, known for its high-quality formulation. | Often favored by experienced aquarists. |

| GE Silicone I (100% Silicone, No Additives) | 1-2 hours | 24-48 hours | Very Good, when verified to be pure silicone. | Requires careful verification of product specifications. |

“Full cure typically requires 24-48 hours in a well-ventilated area at room temperature. Avoid disturbing the sealant during this period.”

The curing times listed are approximate and can vary based on humidity, temperature, and the thickness of the bead applied. Durability refers to the sealant’s ability to withstand constant submersion, water pressure, and temperature fluctuations over time, generally expected to last for many years when properly applied. Always refer to the manufacturer’s instructions for specific curing times and application guidelines.

End of Discussion

Successfully resealing a leaking aquarium seam is a rewarding endeavor that restores both the aesthetic appeal and functional integrity of your aquarium. By diligently following the Artikeld steps, from meticulous preparation and safe sealant application to proper curing and careful refilling, you ensure a robust and watertight seal. This process not only safeguards your aquatic ecosystem but also provides peace of mind, allowing you to fully enjoy the beauty of your thriving underwater display for years to come.

Remember that preventative maintenance and prompt attention to any signs of wear are key to avoiding future issues.