Welcome to our comprehensive guide on achieving a tranquil aquatic environment. We understand that the gentle hum of a healthy aquarium can be soothing, but excessive noise from filters and pumps can detract from the serene experience. This content is meticulously prepared to address those bothersome sounds, offering practical solutions for a peaceful coexistence with your underwater world.

This exploration delves into the common sources of aquarium noise, guiding you through the process of identifying the specific culprits within your filtration and pumping systems. We will then present a series of actionable strategies, ranging from simple maintenance tweaks to more involved modifications, all designed to significantly reduce the audible disturbances emanating from your aquarium equipment.

Understanding Aquarium Noise Sources

Aquarium filters and pumps are essential for maintaining a healthy aquatic environment, but they can also be a significant source of noise. Understanding the origins of this sound is the first step toward mitigating it. This section will break down the common components that contribute to aquarium noise and the mechanisms by which they produce sound.The operation of aquarium equipment involves moving parts and the interaction of water and air, both of which are primary generators of audible sound.

By identifying the specific sources, we can then implement targeted solutions to create a more peaceful viewing experience.

Filter and Pump Components Generating Noise

Several key components within aquarium filtration and pumping systems are responsible for the sounds we hear. These include the motor, impeller, housing, and air intake systems. Each of these parts plays a role in the overall noise profile of the equipment.The motor, a fundamental part of most pumps, generates noise through the rotation of its internal components, such as the rotor and bearings.

The impeller, which is driven by the motor to move water, can also create noise as it spins, especially if it becomes unbalanced or encounters debris. The filter housing and pump casing can amplify or resonate with these vibrations, further contributing to the audible sound. Additionally, some filters incorporate air intake mechanisms for oxygenation, which can produce gurgling or sputtering sounds.

Mechanisms of Sound Production

The sounds produced by aquarium filters and pumps arise from a combination of mechanical vibrations and fluid dynamics. Mechanical vibrations are generated by moving parts, while fluid dynamics contribute to noises related to water flow and air entrainment.Mechanical noise is often a result of the motor’s operation. Bearings can develop wear, leading to grinding or rattling sounds. The impeller’s rotation can create a humming or whirring noise.

If the impeller is not perfectly balanced or if it strikes debris, it can produce a more distinct rattling or thumping sound.Fluid dynamic noise occurs as water is moved through the filter and pump system. The rapid movement of water can create turbulence, leading to gurgling or splashing sounds. When air is introduced into the water flow, particularly in hang-on-back filters or those with air stones, it can result in a sputtering or bubbling noise.

Types of Aquarium Equipment Noise

The sounds emanating from aquarium filters and pumps can be categorized into several distinct types, each with its own characteristic acoustic signature. Recognizing these sounds helps in diagnosing the source of the noise.Common noise types include:

- Humming: Often associated with the motor’s operation, a consistent low-frequency sound.

- Rattling: Can indicate loose parts, debris within the impeller, or a worn bearing.

- Gurgling: Typically caused by air bubbles being trapped and released within the water flow, especially in filter intakes or outlets.

- Vibrating: A low-frequency thrumming sound that can occur when the equipment is not properly secured or when its housing resonates with the motor’s vibrations.

- Sputtering: Similar to gurgling, but often more intermittent and associated with inconsistent air intake or water flow.

Identifying the Specific Noise Culprit

Once you’ve established that your aquarium filter and pump are the likely sources of noise, the next crucial step is to pinpoint the exact component causing the disturbance. This systematic approach will help you address the issue efficiently without unnecessary adjustments to other parts of your setup. By carefully listening and observing, you can distinguish between different types of sounds and their origins.A common challenge in aquarium maintenance is the presence of unwanted noise.

While some ambient hum is expected from mechanical equipment, excessive or unusual sounds often indicate a problem that needs attention. Isolating the specific source of this noise is key to finding an effective solution, whether it’s a simple adjustment or a component replacement.

Pinpointing the Exact Source of Aquarium Noise

To effectively identify the source of noise, a methodical approach is recommended. This involves isolating different components of your filtration system and observing the sound under controlled conditions. By systematically eliminating potential culprits, you can narrow down the possibilities to the specific part that is generating the noise.The process begins with keen observation and listening. Many aquarium noises are distinct and can be traced by carefully paying attention to where they originate.

- Listen Intently: Before touching anything, spend a few minutes simply listening to your aquarium. Try to identify the direction and nature of the sound. Is it a constant hum, a rattling, a buzzing, or a gurgling?

- Isolate Components: If possible, temporarily disconnect or silence individual components of your filter system one by one. For example, if you have a hang-on-back filter with a separate powerhead, you could briefly turn off the powerhead to see if the noise stops.

- Check the Pump Housing: For internal or external canister filters, the pump is often housed within the filter body. Vibrations from the pump motor can transfer to the filter casing and the aquarium itself.

- Examine the Impeller: The impeller is a rotating component within the pump that moves water. If it’s damaged, worn, or has debris caught in it, it can create a rattling or grinding noise.

- Inspect Tubing and Hoses: Air bubbles trapped in tubing, or tubing vibrating against the aquarium glass or stand, can create gurgling or rattling sounds.

- Evaluate the Filter Media: While less common, sometimes loosely packed filter media can shift and cause a slight rustling or rattling sound.

Troubleshooting to Isolate the Filter or Pump

Differentiating between the filter and the pump as the primary noise generator is a critical step in the troubleshooting process. This distinction is important because the solutions for each component can vary significantly. By carefully observing the sound when specific parts are running or stopped, you can effectively isolate the problematic unit.This isolation process helps in focusing your efforts on the correct piece of equipment, saving time and potential frustration.

- Simultaneous Operation Test: Run both the filter and the pump simultaneously and note the overall noise level and type.

- Filter Only Test: If your setup allows, run the filter without the pump (if they are separate units) or with the pump on a low setting. Listen for any noise.

- Pump Only Test: If possible, run the pump independently of the filter to assess its noise contribution. For integrated systems, this might involve temporarily removing the filter media to see if the pump’s noise changes.

- Water Flow Disruption: Sometimes, reducing the water flow from the filter or pump can help identify if the noise is related to the water movement itself rather than the motor.

Differentiating Mechanical Noise from Water Flow Noise

Understanding the difference between mechanical noise and water flow noise is fundamental to effective troubleshooting. Mechanical noise typically originates from moving parts within the pump or filter, while water flow noise is a result of water’s movement through the system and its interaction with the aquarium environment. Recognizing these distinctions will guide you toward the correct solution.Mechanical noise is often characterized by vibrations, grinding, or rattling, whereas water flow noise tends to be more of a gurgling, bubbling, or rushing sound.

Mechanical Noise Characteristics:

Mechanical noise is usually a direct result of the motor and its moving parts.

- Grinding or Scraping: This often indicates an issue with the impeller, such as debris caught in it or wear and tear on the impeller shaft or housing.

- Rattling or Buzzing: This can be caused by loose components within the filter or pump housing, or by vibrations from the motor that are not being adequately dampened. It might also signify an imbalance in the impeller.

- Humming: A low, constant hum is typical for most electric motors. However, an unusually loud or fluctuating hum can point to motor strain or an issue with the motor bearings.

Water Flow Noise Characteristics:

Water flow noise is related to the movement of water and air within the filtration system and aquarium.

- Gurgling or Bubbling: This is commonly caused by air being drawn into the pump intake or trapped within the filter’s water pathways. It can also occur if the water level in the filter is too low.

- Rushing or Roaring: Excessive water flow hitting the surface of the aquarium can create a loud rushing sound, especially if the filter outlet is not submerged or is creating a waterfall effect.

- Splashing: This occurs when water is falling from a height into the aquarium, often from the filter outlet.

- Vibrations through Water: Sometimes, the vibrations from a mechanical component can be transmitted through the water, creating a low thrumming sound that might be mistaken for water flow noise.

Reducing Filter Noise

Now that we’ve identified the sources of noise from your aquarium filter and pump, let’s delve into practical strategies for reducing them. Filters are essential for a healthy aquarium, but their operation can sometimes be a significant contributor to unwanted sound. This section will guide you through various methods to quiet down your filtration system.A well-maintained and properly configured filter is key to minimizing noise.

We will explore common filter types, specific adjustments, and maintenance routines that can dramatically improve the acoustic environment of your aquarium setup.

Common Filter Types and Noise Reduction Techniques

Different filter designs inherently produce different types of noise. Understanding these variations allows for targeted solutions.

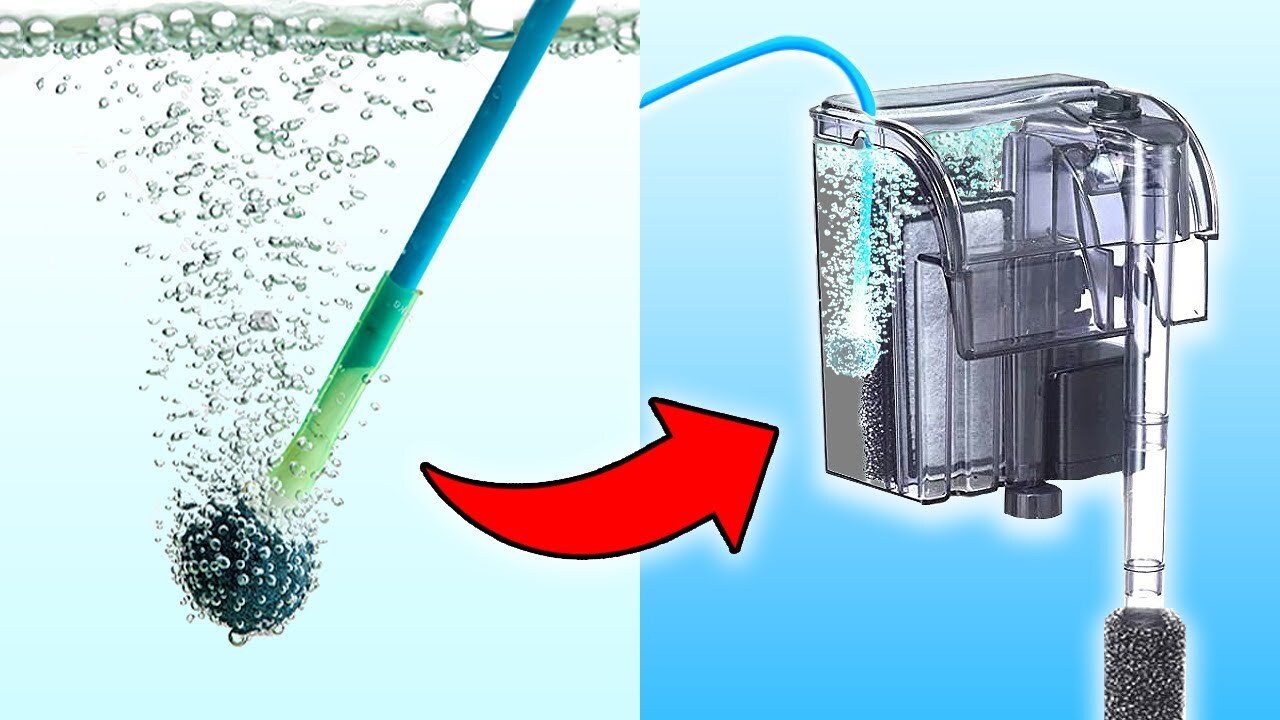

- Hang-on-Back (HOB) Filters: These are popular for their ease of use and effectiveness. Noise often arises from water cascading into the filter box and vibrations from the motor. To reduce noise, ensure the filter intake tube reaches below the water surface to minimize splashing. Adjusting the outflow nozzle to direct water flow against the glass or a decor piece can also diffuse the sound of falling water.

Some HOB filters also benefit from adding filter media or sponges to the outflow to further dampen water noise.

- Internal Filters: Typically placed inside the aquarium, these filters can generate motor hum and bubbling sounds. Securing the filter firmly to the glass with suction cups can reduce vibrations. For bubbling noises, ensure the air intake (if applicable) is not submerged too deep or is positioned to avoid excessive turbulence.

- Canister Filters: These external filters are known for their quiet operation when properly set up. Noise often comes from the pump, air trapped within the filter, or vibrations from the housing. Regularly bleeding air from the canister is crucial. Ensure all seals are tight to prevent air ingress. Placing the canister on a foam mat can absorb vibrations.

- Sponge Filters: Powered by an air pump, sponge filters are generally very quiet. The primary noise source is usually the air pump itself. Positioning the air pump on a vibration-dampening mat or hanging it can reduce noise.

Impeller Condition and Maintenance

The impeller is the heart of most aquarium filters, responsible for moving water. Its condition directly impacts both filter performance and noise levels.A worn or dirty impeller can lead to a less efficient pump and increased noise due to imbalance or friction. Regular cleaning and inspection are vital for optimal performance and quiet operation.

Impeller Maintenance Procedure

Follow these steps to clean and maintain your filter’s impeller:

- Turn off the filter and unplug it. Safety first is paramount when working with electrical equipment and water.

- Disassemble the filter head or pump housing. Refer to your filter’s manual for specific instructions.

- Carefully remove the impeller. Note its orientation if it’s not a simple cylindrical shape.

- Inspect the impeller and the impeller well for debris, algae, or mineral deposits. Gently clean these parts with a soft brush (an old toothbrush works well) and aquarium-safe water. Avoid using soaps or detergents, as these can be toxic to aquarium inhabitants.

- Check the impeller shaft and well for wear or damage. If either is significantly worn or cracked, replacement might be necessary.

- Lubricate the impeller shaft (if applicable). For some filter models, a tiny amount of aquarium-safe silicone lubricant can be applied to the shaft to ensure smooth rotation. Do not over-lubricate.

- Reassemble the filter head or pump housing. Ensure all parts are correctly aligned and seals are properly seated.

- Prime the filter if necessary and restart the filter. Listen for any unusual noises.

Filter Intake and Outflow Modifications

The way water enters and exits your filter significantly influences noise. Minimizing turbulence at these points is key to a quieter operation.Adjusting the intake and outflow can prevent the creation of disruptive water movements that lead to splashing and gurgling sounds.

- Intake Modifications: Ensure the intake strainer is fully submerged to prevent air from being drawn into the system, which causes gurgling. For HOB filters, lowering the intake tube further into the water can help. Some hobbyists add a sponge or pre-filter to the intake to further diffuse the water entry and reduce noise.

- Outflow Modifications: The sound of water returning to the aquarium is a common noise source. For HOB filters, directing the outflow against the aquarium glass or a piece of decor can break up the water’s fall and soften the sound. You can also try attaching a spray bar to the outflow, which disperses the water more gently. For canister filters, ensure the outflow nozzle is positioned to avoid creating excessive surface agitation or splashing.

Cleaning and Lubricating Filter Components

Regular maintenance is the most effective way to keep your filter running quietly and efficiently.A clean filter operates with less friction and less resistance, leading to reduced noise. Lubrication, when appropriate, ensures smooth movement of parts.

Step-by-Step Filter Cleaning and Lubrication

- Safety First: Unplug the filter and remove it from the aquarium.

- Disassembly: Carefully take apart the filter according to the manufacturer’s instructions. This usually involves separating the pump head from the filter body or canister.

- Rinse Media: Rinse all filter media (sponges, cartridges, bio-rings) in old aquarium water that you’ve siphoned out. Never use tap water, as chlorine can kill beneficial bacteria.

- Clean Impeller and Housing: As detailed previously, clean the impeller and its housing. Ensure all debris is removed.

- Inspect Seals: Check all rubber seals and gaskets for wear or damage. Replace any that are cracked or hardened.

- Lubricate (if applicable): Apply a small amount of aquarium-safe silicone lubricant to the impeller shaft or any moving parts as recommended by the manufacturer.

- Reassembly: Put the filter back together, ensuring all parts are correctly seated and seals are in place.

- Priming and Restart: Prime the filter if necessary and then plug it back in and restart it.

Dampening Vibrations from External Filter Housings

External filter housings, particularly those of canister filters, can transmit vibrations to the aquarium stand and surrounding surfaces, creating a low-frequency hum.Addressing these vibrations can significantly reduce the overall noise perceived from your filtration system.

- Placement on a Mat: Place the external filter on a thick, dense foam mat or a rubber vibration-dampening pad. This acts as a buffer, absorbing vibrations before they can transfer to the stand. Exercise mats or specialized aquarium filter mats are good options.

- Secure Mounting: Ensure the filter is placed on a stable and level surface. If the stand has any loose panels or components, securing them can prevent them from rattling and amplifying vibrations.

- Internal Padding: For some canister filters, adding a layer of foam or dense filter material inside the filter housing (away from the water flow path) can help dampen internal vibrations from the motor. This should be done cautiously and only if it doesn’t impede water flow or maintenance.

- Check for Loose Parts: Periodically inspect the external filter housing for any loose screws or connections that might be vibrating. Tighten them as needed.

Reducing Pump Noise

While filters are a common source of aquarium noise, the pump itself can also be a significant contributor. Understanding the mechanics of pump operation and addressing potential issues can lead to a much quieter aquatic environment. This section will delve into common causes of pump noise and offer practical solutions.

Optimizing Water Flow and Aeration for Quietness

Achieving a tranquil aquarium environment often hinges on managing the sounds generated by water movement. The way water exits your filter and pump, and how it interacts with the surface, plays a significant role in the overall noise level. By carefully adjusting these elements, you can create a serene underwater world that is both healthy for your inhabitants and pleasant for you to enjoy.The interplay between water level, flow rate, and the design of your filter’s output directly influences the audible disturbances within your aquarium.

A turbulent water surface, often caused by a high flow rate or an improperly directed output, can lead to splashing, gurgling, and other disruptive noises. Conversely, a controlled and gentle water flow can minimize these sounds, creating a more peaceful atmosphere.

Water Level and Flow Rate Impact on Filter Output Noise

The height of your aquarium’s water level and the speed at which water is expelled from your filter are critical factors in noise generation. When the water level is too low, the water may fall a greater distance from the filter’s output, increasing splashing and aeration sounds. Similarly, a high flow rate can overwhelm the surface, causing turbulence and audible disruptions.

Finding the right balance ensures efficient filtration without creating an unpleasant auditory experience.It is important to understand that a higher flow rate is not always better. While it can ensure rapid water turnover, it often comes at the cost of increased noise. The ideal flow rate is one that effectively circulates and filters the water without causing excessive agitation at the surface.

This is particularly true for the output of hang-on-back filters and canister filters, where the water’s reentry into the tank is most noticeable.

Adjusting Spray Bars and Output Nozzles for Quieter Water Flow

The orientation and design of your filter’s output mechanism, such as spray bars or nozzles, offer a direct avenue for noise reduction. By strategically angling these components, you can direct the water flow away from the surface or towards an area where it will be diffused more gently. This minimizes the impact and subsequent noise upon hitting the water.Methods for achieving a gentler, quieter water flow include:

- Angling Spray Bars Downwards: Directing the spray bar slightly downwards towards the substrate or a decorative element can break up the initial force of the water, reducing splashing and surface agitation.

- Utilizing a Lily Pipe or Surface Skimmer: These specialized output devices are designed to create a laminar flow, which is a smooth, unbroken stream of water. This type of flow is significantly quieter than turbulent, aerated streams. Lily pipes, in particular, can create a gentle, wave-like motion on the surface without excessive noise.

- Adjusting Nozzle Position: For filters with simple output nozzles, experimenting with their position can yield results. Try pointing them parallel to the water surface or slightly angled to avoid direct impact.

- Adding Decorations: Placing rocks, driftwood, or plants near the filter output can help to diffuse the water flow, breaking up the force and reducing noise.

Achieving Adequate Aeration Without Excessive Splashing or Gurgling

Aeration is vital for the health of your aquarium inhabitants, providing essential oxygen. However, the methods used to achieve it can sometimes lead to unwanted noise. The goal is to introduce oxygen efficiently while minimizing the disruptive sounds associated with vigorous water movement.Effective aeration without excessive noise can be achieved through:

- Surface Agitation: A gently rippling water surface is ideal for gas exchange. This can be achieved by ensuring a slight flow that causes subtle movement, rather than a cascade of falling water.

- Air Stones and Diffusers: While air stones themselves can produce a slight bubbling sound, the bubbles they create are fine and rise through the water column, facilitating oxygen diffusion without significant surface disruption. Positioning an air stone near the filter output can also help to further break up the water flow and reduce noise.

- Controlled Filter Output: As discussed previously, a well-directed filter output can contribute to surface agitation and aeration. A gentle, consistent flow that causes subtle ripples is more conducive to quiet operation than a forceful, splashing stream.

Visual Description of Ideal Water Surface Movement for Quiet Operation

Imagine the surface of your aquarium water as a calm, tranquil pond on a windless day. The ideal water surface for quiet operation is characterized by a gentle, consistent movement that suggests healthy gas exchange without any signs of disturbance. Instead of dramatic splashes or noisy gurgles, you should observe subtle, slow-moving ripples that continuously refresh the water’s surface.Think of it as a soft, almost imperceptible undulation, like the surface of a lake just after a light breeze has passed.

There should be no visible spray or chaotic churning. The water should appear to be breathing, with a steady, rhythmic rise and fall that allows for efficient oxygenation and carbon dioxide release without the auditory accompaniment of vigorous splashing or the hollow sound of water falling from a height. This serene movement ensures a peaceful environment for both your aquatic life and yourself.

Material and Placement Strategies for Noise Dampening

Beyond addressing the mechanical aspects of your filter and pump, the physical environment surrounding your aquarium equipment plays a crucial role in noise reduction. Strategic use of sound-dampening materials and thoughtful placement can significantly minimize the perceived noise, creating a more serene aquatic display. This section explores effective methods to achieve this.The principles of acoustics dictate that sound can be absorbed, blocked, or redirected.

By understanding these principles, we can select and implement materials and placement techniques that effectively mitigate the vibrations and airborne noise generated by aquarium equipment.

Sound-Dampening Materials for Aquarium Environments

Various materials can effectively absorb or block sound waves. The key is to choose options that are safe for aquarium use, resistant to moisture, and aesthetically pleasing.Here are some common and effective sound-dampening materials suitable for aquarium setups:

- Acoustic Foam Panels: These are specifically designed to absorb sound waves. They come in various profiles (e.g., egg crate, pyramid) that increase surface area for better absorption. They are lightweight and can be easily cut to size.

- Mass Loaded Vinyl (MLV): This is a dense, flexible barrier material that is highly effective at blocking sound transmission. It’s often used in construction for soundproofing and can be draped or affixed to create barriers.

- Closed-Cell Foam (e.g., EVA foam, neoprene): These foams are excellent at absorbing vibrations and have good moisture resistance. They can be used as padding under equipment or as part of a custom enclosure.

- Rubber Mats: Dense rubber mats, similar to those used for exercise equipment or anti-vibration pads, can effectively dampen vibrations from pumps and filters placed directly on them.

- Fiberglass or Mineral Wool Insulation (with caution): While highly effective sound absorbers, these materials can be problematic in a humid aquarium environment if not properly enclosed, as they can absorb moisture and become a breeding ground for mold. If used, they must be completely sealed within a moisture-proof barrier.

- Cork Sheets: Natural cork is a good sound absorber and vibration dampener. It’s also naturally resistant to moisture and has an appealing aesthetic.

Creating Barriers and Enclosures for Noisy Equipment

The most effective way to reduce noise is to contain it. Building simple barriers or enclosures around your filter and pump can dramatically lower the sound output.The following methods can be employed to construct effective sound-dampening enclosures:

- DIY Enclosures: Construct a box or cabinet using MDF (Medium-Density Fibreboard) or plywood. Line the interior with acoustic foam panels or MLV to maximize sound absorption. Ensure adequate ventilation to prevent overheating of the equipment.

- Vibration-Dampening Mounts: Place noisy equipment on rubber mats or specialized anti-vibration feet. This isolates the equipment from the surface it rests on, preventing vibrations from traveling and amplifying.

- Targeted Barriers: For equipment that cannot be fully enclosed, strategically place dense materials like MLV sheets or thick cork boards behind or around the source of the noise to block its direct path.

- Aquarium Cabinets: Many commercial aquarium stands and cabinets are designed with sound dampening in mind. If you are purchasing a new setup, consider one with a well-insulated cabinet.

Comparison of Sound-Absorption Properties

The effectiveness of sound-dampening materials can vary significantly. While a comprehensive scientific comparison requires specialized testing, the following table provides a general overview of common materials and their relative sound-absorption capabilities.

| Material | Primary Sound Reduction Method | Typical Effectiveness | Moisture Resistance | Ease of Use |

|---|---|---|---|---|

| Acoustic Foam Panels | Absorption | Good (especially for higher frequencies) | Moderate (can absorb moisture if not treated) | High |

| Mass Loaded Vinyl (MLV) | Blocking (Mass) | Excellent (especially for lower frequencies) | Excellent | Moderate (can be heavy and difficult to cut) |

| Closed-Cell Foam (EVA, Neoprene) | Absorption & Vibration Dampening | Good | Excellent | High |

| Dense Rubber Mats | Vibration Dampening | Good | Excellent | High |

| Cork Sheets | Absorption & Vibration Dampening | Good | Good | High |

Strategic Equipment Placement for Noise Minimization

The location of your aquarium filter and pump can influence how much noise you perceive. Thoughtful placement can help to mask or redirect sound, making it less noticeable.Consider the following placement strategies to reduce noise perception:

- Away from Walls: Placing equipment directly against a wall can cause sound to reverberate and amplify. Position equipment slightly away from walls to allow sound to dissipate.

- Behind Decorative Elements: Utilize the aquarium stand or strategically placed decor (if external) to create a natural barrier that blocks or diffuses sound.

- Lowering Equipment: Generally, noise travels upwards. Placing equipment on lower shelves or the floor within a cabinet can reduce the direct path of sound to your ears.

- Isolating from Resonant Surfaces: Avoid placing noisy equipment on hollow or thin surfaces that can easily vibrate and amplify sound.

- Considering Room Acoustics: In open-plan rooms, noise can travel further. In such environments, creating a dedicated enclosure or barrier becomes even more critical.

Maintenance Practices for Sustained Quiet Operation

Maintaining your aquarium filter and pump regularly is paramount to ensuring they operate quietly and efficiently. Proactive care not only prevents disruptive noises but also extends the lifespan of your equipment and contributes to a healthier aquatic environment. A consistent maintenance routine addresses potential issues before they escalate into significant problems.This section will detail the essential maintenance practices that will help you keep your aquarium filter and pump running as silently as possible.

By adhering to a structured schedule and being vigilant about the condition of your equipment, you can significantly reduce the likelihood of noise disturbances.

Routine Maintenance Schedule

Establishing a routine maintenance schedule is the most effective way to prevent future noise issues from developing. This involves regular cleaning, inspection, and servicing of your aquarium’s filtration and pump systems. Consistency is key to ensuring long-term quiet operation.Here is a suggested maintenance schedule, which can be adjusted based on the specific type of equipment you use and the demands of your aquarium:

- Weekly: Briefly inspect the pump and filter for any obvious signs of wear, loose parts, or unusual vibrations. Check water flow to ensure it hasn’t diminished.

- Bi-weekly: Perform a partial water change and use this opportunity to rinse filter media in old tank water (never tap water, as chlorine can kill beneficial bacteria). Clean the intake strainer of the pump to prevent clogging.

- Monthly: Disassemble and thoroughly clean the filter housing and pump impeller. Check impeller shaft for any debris or damage. Inspect seals and gaskets for wear.

- Quarterly: Examine impeller and any other moving parts for signs of wear. Consider replacing impeller if it shows significant wear or if noise has begun to increase. Clean all tubing and connectors.

- Annually: A more in-depth inspection of the entire system. Consider replacing certain components if they are nearing the end of their expected lifespan, even if they are not yet causing audible noise.

Proactive Replacement of Worn-Out Parts

Worn-out parts are a primary culprit behind increased noise in aquarium filters and pumps. Components like impellers, bearings, and seals degrade over time, leading to imbalances and vibrations that translate into audible noise. Proactive replacement, rather than waiting for a part to fail or become excessively noisy, is a more effective strategy.

“Replacing worn parts before they cause significant noise or equipment failure is an investment in quiet operation and equipment longevity.”

Key components to monitor and consider for proactive replacement include:

- Impellers: These spin at high speeds and are subject to wear and tear. A chipped or unbalanced impeller will vibrate and cause noise. Many manufacturers recommend impeller replacement every 1-2 years, depending on usage and water quality.

- Bearings: If your pump has accessible bearings, listen for any grinding or humming sounds. While often sealed, some can be lubricated or replaced.

- Seals and Gaskets: Deteriorated seals can lead to leaks, which can sometimes be accompanied by gurgling or unusual pump sounds. Replacing them ensures a tight fit and prevents air ingress.

- Vibration Dampening Pads: If your pump or filter came with rubber or foam pads, inspect them for signs of compression or degradation. Replacing these can significantly reduce vibration transfer to the aquarium stand.

Regular Inspections for Loose Components or Leaks

Consistent visual and auditory inspections are crucial for identifying potential noise sources early on. Loose components can vibrate against the aquarium or stand, creating a persistent hum or rattle. Leaks, even small ones, can cause air to be drawn into the system, leading to gurgling sounds.During your regular maintenance checks, pay close attention to the following:

- Secure Mounting: Ensure that the filter and pump are securely attached to the aquarium or stand. Check that all mounting clips, brackets, or suction cups are in good condition and firmly in place. Loose equipment is a common source of vibration noise.

- Tubing and Hoses: Verify that all tubing and hoses are properly connected and not vibrating against any surfaces. Secure them with clips if necessary to prevent movement.

- Impeller Housing: Make sure the impeller housing is correctly seated and that there are no gaps where parts could be loose.

- Water Level: Ensure the water level in the aquarium is maintained at an appropriate height. If the water level is too low, the pump intake can suck in air, causing a noisy gurgling sound.

- Signs of Leaks: Look for any drips, moisture, or water stains around the filter, pump, and tubing connections. Even minor leaks can indicate a problem that might eventually lead to noise.

Epilogue

By implementing the techniques discussed, you can transform your noisy aquarium into a haven of tranquility. From understanding the root causes of sound to applying specific reduction methods for filters and pumps, and finally optimizing your setup for quiet operation, this guide equips you with the knowledge to enjoy the beauty of your aquarium without the distraction of unwanted noise.

Embrace these practices for a consistently peaceful and visually captivating aquatic display.