Embarking on the journey of creating your own aquarium stand is a rewarding endeavor, offering both practical benefits and the satisfaction of a custom-built centerpiece for your aquatic world. This guide delves into the essential considerations, from understanding structural integrity to selecting the right materials, ensuring your aquarium is housed safely and stylishly.

We will navigate through the planning stages, helping you design a blueprint tailored to your specific needs, whether it’s for a modest freshwater setup or a more demanding saltwater reef tank. The subsequent steps will provide a clear, actionable roadmap for construction, covering everything from lumber preparation to the finer details of finishing and customization.

Understanding the Fundamentals of Aquarium Stand Construction

Building a stable and functional aquarium stand is paramount to the safety and longevity of your aquatic ecosystem. A well-constructed stand not only supports the immense weight of a filled aquarium but also provides essential features for maintenance and equipment management. This section delves into the core principles that underpin successful DIY aquarium stand projects.The structural integrity of an aquarium stand is its most critical attribute.

Water is surprisingly heavy, and when combined with the glass or acrylic tank, substrate, and decorations, the total weight can be substantial. For instance, a 55-gallon aquarium filled with water can weigh over 500 pounds. Therefore, the stand must be engineered to distribute this weight evenly and prevent any sagging or structural failure. Key considerations include the load-bearing capacity of the materials, the strength of the joints, and the overall stability of the design.

Structural Considerations for Weight Support

Supporting the weight of a filled aquarium requires careful planning regarding the stand’s dimensions and internal bracing. The primary goal is to prevent deflection or bending of the top surface, which can lead to stress on the aquarium itself. This is typically achieved through a combination of robust framing and strategic support members. For larger aquariums, internal crossbeams or a solid top panel are often necessary to ensure uniform weight distribution and prevent the top from bowing under pressure.

The legs of the stand must also be strong enough to bear the load and be positioned to provide maximum stability, preventing any tipping.

Common Materials for Aquarium Stand Construction

The choice of materials significantly impacts the durability, aesthetics, and cost of your DIY aquarium stand. Each material offers distinct advantages and disadvantages that should be weighed against your project’s requirements and your skill level.Here is a list of common materials used in aquarium stand construction and their associated pros and cons:

- Solid Wood: This is a popular choice for its strength, aesthetic appeal, and workability.

- Pros: High load-bearing capacity, can be stained or painted to match decor, relatively easy to work with using standard woodworking tools, good aesthetic versatility.

- Cons: Can be susceptible to moisture damage if not properly sealed, can be more expensive than composite materials, requires proper joinery techniques for maximum strength. Common woods include pine, poplar, oak, and maple.

- Plywood: High-quality plywood, especially cabinet-grade or hardwood plywood, offers excellent strength and stability.

- Pros: Strong and stable, available in various thicknesses, less prone to warping than solid wood, can be a more cost-effective option for larger panels.

- Cons: Edges require finishing to prevent delamination, may not offer the same aesthetic as solid wood unless veneered or painted, can be heavy.

- MDF (Medium-Density Fiberboard): While not ideal for structural components bearing direct load, MDF can be used for decorative panels or shelves within a sturdier frame.

- Pros: Smooth surface for painting, consistent density, relatively inexpensive.

- Cons: Very susceptible to water damage and swelling, low structural strength on its own, heavy, can create fine dust when cut.

- Metal (Steel or Aluminum): Metal frames can offer exceptional strength and a modern aesthetic.

- Pros: Extremely strong and durable, can support very heavy loads, resistant to moisture.

- Cons: Requires specialized tools and welding skills for fabrication, can be expensive, may require a protective coating to prevent rust (steel) or corrosion.

Ventilation and Equipment Access

Proper ventilation within an aquarium stand is crucial for maintaining a healthy environment for both the inhabitants and the equipment. Overheating can be a significant issue, especially for electronic components like filters, heaters, and lights. Poor airflow can lead to reduced equipment lifespan and potential malfunctions. Furthermore, easy access to the back of the aquarium and the equipment housed within the stand is essential for routine maintenance, water changes, and troubleshooting.Considerations for ventilation include the inclusion of vents, louvers, or open-back designs to promote air circulation.

For equipment access, doors, removable panels, or open shelving can be incorporated. It is also beneficial to plan for cable management to keep wiring neat and organized, preventing potential hazards.

Common Tools and Safety Equipment

Embarking on a DIY aquarium stand project requires a foundational set of tools and a commitment to safety. Having the right equipment will not only make the construction process smoother but also ensure a higher quality and safer final product.The following is a list of common tools and essential safety equipment needed for building a DIY aquarium stand:

- Measuring and Marking Tools:

- Tape measure

- Pencil

- Carpenter’s square

- Level

- Cutting Tools:

- Circular saw or miter saw (for wood)

- Jigsaw (for curves or cutouts)

- Hand saw (for smaller cuts)

- Drilling and Fastening Tools:

- Power drill/driver

- Drill bits (various sizes)

- Screwdriver set

- Clamps (various types for holding pieces together)

- Hammer

- Finishing Tools:

- Sandpaper (various grits)

- Sander (orbital or belt)

- Paintbrushes or rollers

- Safety Equipment:

- Safety glasses or goggles

- Work gloves

- Dust mask or respirator

- Hearing protection (when using power tools)

- Sturdy work boots

Always ensure your workspace is well-lit and free from clutter. When operating power tools, always read and understand the manufacturer’s instructions and follow best practices for safe operation.

Planning Your DIY Aquarium Stand Design

Careful planning is the cornerstone of a successful DIY aquarium stand project. This stage involves translating your needs and the aquarium’s specifications into a concrete design that is both functional and aesthetically pleasing. A well-thought-out plan minimizes errors during construction and ensures the final product is safe and sturdy.This section will guide you through the essential steps of designing your aquarium stand, from conceptualizing a basic blueprint to adapting it for various aquarium setups and incorporating practical storage solutions.

We will also address common design challenges and how to proactively mitigate them.

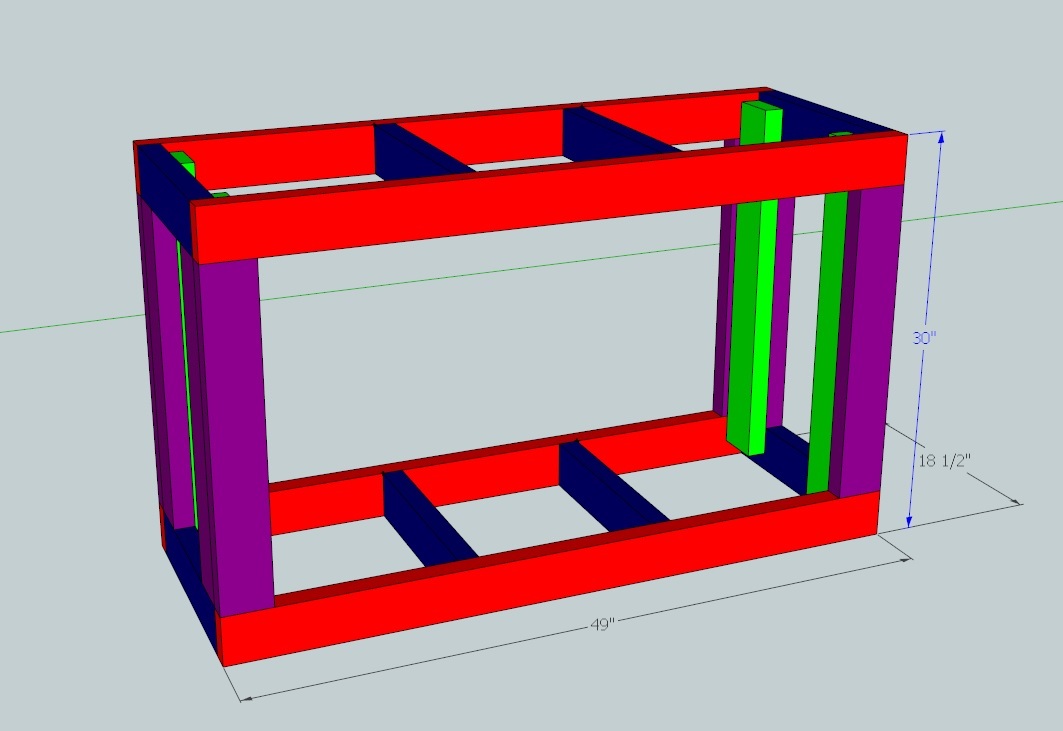

Basic Blueprint for a 55-Gallon Freshwater Aquarium Stand

Designing a stand for a standard 55-gallon freshwater aquarium requires attention to weight distribution, material strength, and adequate space. A common and effective design is a simple rectangular frame with internal bracing for support.A typical 55-gallon aquarium measures approximately 48 inches in length, 13 inches in width, and 21 inches in height. The total weight of a 55-gallon aquarium filled with water, substrate, and decorations can easily exceed 500 pounds.

Therefore, the stand must be robust enough to safely support this load.Here is a blueprint for a basic stand suitable for a 55-gallon aquarium:

- Overall Dimensions:

- Length: 50 inches (providing a 1-inch overhang on each side for aesthetics and easier handling)

- Width: 15 inches (providing a 1-inch overhang on each side)

- Height: 30 inches (a comfortable height for viewing and maintenance, also standard for many furniture pieces)

- Material Recommendations:

- Frame: 2×4 or 2×6 lumber is highly recommended for its strength and availability. For a 55-gallon tank, 2x4s are generally sufficient if properly braced.

- Top Surface: A double layer of 3/4-inch plywood or a single layer of 1-inch thick plywood provides a strong, stable surface to place the aquarium.

- Bracing: Additional 2x4s for internal bracing are crucial for stability.

- Construction Details:

- Legs: Four corner legs constructed from 2x4s.

- Apron: Horizontal pieces connecting the legs at the top, creating a frame.

- Internal Support: A central support beam running the length of the stand, attached to the apron and extending down to a lower brace, is vital for preventing bowing of the top surface. Additional cross braces can be added.

- Bottom Shelf: An optional lower shelf can be constructed from plywood or 1x4s for additional storage or structural support.

Adapting Stand Designs for Different Aquarium Sizes and Shapes

The fundamental principles of aquarium stand construction remain consistent regardless of the aquarium’s size or shape. However, adjustments in dimensions, material strength, and bracing strategies are necessary to accommodate variations.For larger aquariums, the weight load increases significantly, necessitating the use of thicker lumber (e.g., 2×6 or even 4×4 for legs) and more extensive bracing. The number and placement of internal support beams become critical.

For instance, a 125-gallon tank (typically 72 inches long) will require at least one, if not two, central support beams running its full length to prevent the top from sagging under the immense weight.When adapting a design for different shapes, such as bowfront or corner aquariums, consider the distribution of weight. Bowfront tanks have a curved front, which can concentrate pressure.

Ensure the stand’s top surface is adequately reinforced to handle this. Corner aquariums, often triangular or pentagonal, require a stand with a matching base shape. The internal bracing should be designed to mirror the external shape for optimal support.Considerations for various aquarium types:

- Longer Tanks (e.g., 75-gallon, 125-gallon): Require more substantial longitudinal bracing. A central support beam is essential, and for very long tanks, a secondary beam might be beneficial.

- Taller Tanks (e.g., 40-gallon breeder, 90-gallon tall): While the length and width are primary weight factors, height can influence stability. Ensure the stand’s height is proportional to its footprint to prevent tipping.

- Unusual Shapes (e.g., bowfront, corner, hexagon): The stand’s top surface must precisely match the aquarium’s footprint. Internal bracing should be configured to support the unique stress points of these shapes. For bowfronts, reinforcing the area directly behind the curve is important.

Incorporating Storage Solutions into the Stand’s Structure

Integrating storage into your DIY aquarium stand is a practical way to maximize space and keep your aquarium setup organized. This can range from simple shelves to more elaborate cabinet doors and drawers.When planning for storage, consider what items you typically need to access: fish food, water conditioners, cleaning supplies, filter media, nets, and potentially even a small refrigerator for live food.

The design should allow for easy access to these items while also concealing them for a tidy appearance.Here are common storage solutions and how to incorporate them:

- Open Shelving: The simplest solution is to leave the lower portion of the stand open or create one or two open shelves. This is ideal for larger items like filter buckets or spare filter media. Ensure the shelves are sturdy enough to hold the weight of these items.

- Cabinet Doors: Building a cabinet around the lower section of the stand with hinged doors provides a clean, concealed storage space. You can use plywood or even repurposed cabinet doors. Ensure there is adequate clearance for the doors to open fully.

- Drawers: For smaller items like food containers, test kits, and tools, drawers are an excellent option. These can be built into the stand’s frame. Consider using heavy-duty drawer slides if you anticipate storing heavier items.

- Integrated Sump Access: If you plan to use a sump filtration system, the stand must be designed with ample space and access points for the sump itself, as well as plumbing and equipment. This often involves a larger, open cabinet area.

Potential Challenges in Stand Design and Preventative Measures

While building a DIY aquarium stand can be rewarding, several challenges can arise during the design and construction phases. Proactive identification and planning can help mitigate these issues, ensuring a safe and successful project.One of the most significant challenges is underestimating the weight of the aquarium. Water is heavy, and a 55-gallon tank can weigh over 500 pounds when full.

If the stand is not designed with sufficient strength and bracing, it can bow, warp, or even collapse, leading to a catastrophic tank failure.Another common challenge is ensuring the stand is perfectly level. An uneven stand can put uneven stress on the aquarium glass, potentially leading to cracks.Here are potential challenges and their preventative measures:

- Insufficient Structural Integrity:

- Challenge: The stand is not strong enough to support the weight of the aquarium, leading to bowing or collapse.

- Prevention: Thoroughly research the weight of your specific aquarium size when filled. Use robust lumber (e.g., 2×4 or 2×6 for framing). Incorporate ample internal bracing, including at least one central support beam for tanks longer than 4 feet. Consult online calculators or forums for recommended bracing for specific tank sizes.

- Uneven or Warped Materials:

- Challenge: Using warped or bowed lumber can result in an unstable and uneven stand.

- Prevention: Select straight, knot-free lumber. Inspect each piece for warpage before purchasing. Store lumber properly to prevent further warping.

- Inadequate Top Surface Support:

- Challenge: The top surface of the stand may sag under the weight of the aquarium, especially for longer tanks.

- Prevention: Use thick plywood (3/4-inch minimum, ideally 1-inch) for the top. Consider a double layer of plywood for added rigidity. Ensure the top is well-supported by the stand’s frame and internal bracing.

- Poor Joinery and Fasteners:

- Challenge: Using insufficient or weak fasteners can compromise the stand’s integrity.

- Prevention: Use appropriate screws (e.g., wood screws, lag screws for structural connections) and consider wood glue in addition to screws for stronger joints. Ensure all connections are secure and flush.

- Lack of Leveling Capability:

- Challenge: The stand cannot be properly leveled on an uneven floor.

- Prevention: Design the stand with adjustable leveling feet or incorporate shims into the base design. Ensure the floor where the aquarium will be placed is as level as possible before construction.

- Improper Ventilation for Equipment:

- Challenge: Equipment like filters, heaters, or lighting can overheat if not properly ventilated.

- Prevention: Design the stand with adequate airflow, especially if enclosing equipment within cabinets. Consider incorporating small vents or leaving gaps for air circulation.

Step-by-Step Construction Guide

With your design finalized and materials gathered, it’s time to bring your DIY aquarium stand to life. This section will guide you through the construction process, from cutting your lumber to adding the finishing touches. We’ll break down each stage into manageable steps, ensuring clarity and accuracy for a sturdy and reliable stand.This guide assumes you have basic woodworking tools and a safe workspace.

Always prioritize safety by wearing appropriate protective gear, such as safety glasses and gloves, and ensure your tools are in good working order.

Lumber Cutting and Preparation

Accurate cuts are fundamental to a well-built aquarium stand. Precise measurements and clean cuts will ensure that your frame pieces fit together snugly, creating a strong and stable structure. Before you begin cutting, double-check all your measurements against your design plans.Here’s how to approach lumber preparation:

- Measure Twice, Cut Once: Carefully mark your lumber with a pencil and measuring tape according to the dimensions in your plan. For critical structural pieces, consider using a carpenter’s square to ensure perfectly perpendicular lines.

- Use a Suitable Saw: For straight, clean cuts, a circular saw or a miter saw is ideal. A miter saw offers excellent precision for angled cuts if your design requires them. For smaller pieces or detail work, a handsaw can be used, but it requires more skill to achieve accuracy.

- Ensure Square Cuts: When using a circular saw, a rip fence or a guide can help maintain a straight cutting line. For miter saws, ensure the blade is set to the correct angle (typically 90 degrees for straight cuts).

- Smooth Edges: After cutting, lightly sand any rough edges with sandpaper. This not only improves the appearance but also prevents splinters during assembly.

Main Frame Assembly

The main frame is the backbone of your aquarium stand, providing the primary support for the weight of your aquarium and its contents. Assembling this section correctly is crucial for the overall integrity of the stand. We will focus on creating a robust rectangular or square base and vertical supports.The following techniques are commonly used for joining lumber in stand construction:

- Butt Joints with Screws: This is a straightforward method where the end of one piece of lumber butts up against the face of another. Pre-drilling pilot holes is essential to prevent the wood from splitting, especially near the ends. Use wood screws of appropriate length and gauge for a secure connection. For example, when joining a vertical leg to a horizontal base piece, drive screws through the horizontal piece into the end grain of the vertical leg.

- Pocket Hole Joinery: This method uses a specialized jig to create angled holes in one piece of wood, allowing screws to be driven through that piece into another at an angle. Pocket holes create very strong joints and are often hidden, offering a cleaner aesthetic. This is an excellent choice for joining horizontal and vertical frame members.

- Wood Glue: Always use a high-quality wood glue in conjunction with screws or other fasteners. Apply a thin, even layer of glue to the joining surfaces before screwing them together. Wipe away any excess glue that squeezes out with a damp cloth before it dries.

When assembling the main frame, start with the base or bottom perimeter and then attach the vertical support posts. Ensure each joint is square using a carpenter’s square before permanently fastening.

Adding Bracing and Support Elements

Bracing and additional support elements are vital for preventing any wobbling or sagging of the stand, especially under the significant weight of a filled aquarium. These components distribute the load and reinforce the main frame, ensuring long-term stability.Consider the following bracing strategies:

- Horizontal Bracing: Install horizontal braces along the top and bottom edges of the stand, connecting the vertical posts. These braces add rigidity to the frame.

- Diagonal Bracing: For maximum stability, especially on larger stands, diagonal braces are highly recommended. These are typically installed at the corners, running from a vertical post to a horizontal brace. They effectively resist racking forces.

- Center Support: For tanks longer than 4 feet, a central support beam running front to back is often necessary. This beam will rest on the bottom panel and support the top panel directly under the center of the tank, preventing the top panel from bowing.

- Reinforcing Joints: In high-stress areas, consider using metal L-brackets or corner braces to further reinforce the joints between frame members.

When attaching braces, use the same joining techniques as for the main frame, ensuring they are securely fastened and square to the frame members.

Attaching Top and Bottom Panels

The top and bottom panels provide a finished surface and contribute to the overall structural integrity of the stand. The bottom panel rests on the floor, and the top panel supports the aquarium itself.Here’s how to attach these panels:

- Bottom Panel: Position the bottom panel on top of the assembled base frame. Ensure it is flush with the outer edges of the frame. You can attach it by screwing upwards through the base frame members into the bottom panel. Alternatively, if you’ve designed a recessed bottom panel, ensure it sits within the base frame and is secured from the sides.

- Top Panel: The top panel needs to be exceptionally strong and level. If your design includes a central support, ensure it aligns perfectly with the top panel. Attach the top panel by screwing downwards through the panel into the vertical posts and any horizontal braces at the top of the frame. For added strength and a cleaner look, consider using pocket hole joinery to attach the top panel from underneath the frame.

- Consider a Plywood Sub-Top: For very heavy tanks, some builders opt for a double-layer top. This involves attaching a sturdy plywood sheet first, followed by a more aesthetically pleasing overlay material. This significantly increases the load-bearing capacity.

Ensure both panels are perfectly square and level before final fastening.

Creating Access Points and Doors

Easy access to the inside of your aquarium stand is essential for maintenance, housing equipment like filters and heaters, and managing plumbing. This section details how to incorporate functional and aesthetically pleasing access points.Here are some common methods for creating access:

- Cutouts in Panels: For simpler designs, you can create large cutouts in the front or side panels of the stand’s frame before attaching the panels. These can then be covered with a removable panel or a hinged door.

- Hinged Doors: This is the most common and practical solution. Measure and cut the door opening in the front panel of your stand. Construct a door using similar lumber as your frame, ensuring it fits snugly within the opening. Attach the door to the stand frame using sturdy hinges. Consider using magnetic catches or simple latches to keep the door closed.

- Removable Panels: For less frequent access, a removable panel can be an option. This panel can be held in place with screws that are easily removed or with hidden clips.

- Ventilation: It’s crucial to allow for airflow within the stand to prevent heat buildup from equipment. Consider drilling ventilation holes in the bottom panel or incorporating small vents into the design of your doors or side panels.

When cutting openings for doors or access panels, ensure the surrounding frame remains structurally sound. You may need to add extra bracing around the opening to compensate for the removed material.

Finishing and Customization Techniques

Once your aquarium stand is built and structurally sound, the next crucial step is to apply the finishing touches. This not only protects the wood from the humid aquarium environment but also allows you to personalize the stand to match your home decor. A well-finished stand enhances the overall aesthetic of your aquarium setup, making it a focal point rather than just a functional piece of furniture.This section will guide you through various methods for protecting and beautifying your DIY aquarium stand, ensuring both durability and style.

We will explore different finishing options, decorative enhancements, and essential reinforcement techniques for supporting heavier tanks.

Wood Protection and Appearance Enhancement

Protecting the wood from moisture is paramount to prevent warping, swelling, and rot, which can compromise the stand’s integrity and appearance. Various finishing techniques can achieve this while simultaneously elevating the stand’s visual appeal.There are several effective methods for finishing wood, each offering different levels of protection and aesthetic outcomes. The choice of method often depends on the desired look, the type of wood used, and the environmental conditions.

- Sealing: This is the most fundamental step in protecting wood from moisture. Sealants create a barrier that prevents water from penetrating the wood fibers. Common sealants include polyurethane, varnish, and shellac. Polyurethane is highly durable and water-resistant, making it an excellent choice for aquarium stands. Varnish offers good protection and can provide a glossy or satin finish.

Shellac offers a natural look but is less resistant to water and alcohol.

- Staining: Stains are used to add color to wood. They penetrate the wood, enhancing its natural grain and providing a rich, uniform color. Stains do not offer significant protection on their own; they are typically applied before a sealant. Water-based stains are easier to clean up, while oil-based stains often offer deeper penetration and richer colors.

- Painting: Painting provides a solid color finish and can completely obscure the wood grain. It offers excellent protection against moisture when a good quality primer and topcoat are used. For aquarium stands, it’s essential to use paints that are low in VOCs (Volatile Organic Compounds) and are formulated for durability.

- Oiling: Natural oils like tung oil or linseed oil penetrate the wood, providing a natural, matte finish and some water resistance. While aesthetically pleasing, they require more frequent reapplication than varnishes or polyurethanes and offer less robust protection against direct water exposure.

Paint and Sealant Options for Aquarium Environments

Selecting the right paint and sealant is critical for the longevity and safety of your aquarium stand. The high humidity and potential for water splashes necessitate products that are specifically designed to withstand these conditions.When choosing paints and sealants, consider their water resistance, durability, and the presence of any harmful chemicals that could leach into the aquarium water.

- Polyurethane (Water-Based and Oil-Based): Water-based polyurethanes are low in VOCs, dry quickly, and are easy to clean up. They offer good water and scratch resistance. Oil-based polyurethanes provide a harder, more durable finish and are generally more water-resistant, but they have stronger odors and longer drying times. Both are excellent choices for aquarium stands.

- Marine Varnish: This type of varnish is specifically formulated to withstand harsh marine environments, making it ideal for the high humidity of an aquarium setup. It offers superior UV protection and excellent water resistance.

- Epoxy Resin: For ultimate waterproofing, a two-part epoxy resin can be applied. This creates a thick, durable, and completely waterproof layer. It’s often used for countertops and boat building, offering exceptional protection. However, it can be more challenging to apply evenly and may significantly alter the aesthetic of the wood.

- Acrylic Paints: High-quality acrylic paints, especially those designed for furniture or exterior use, can provide a durable and water-resistant finish when properly sealed. Ensure they are non-toxic once cured.

- Latex Paints: While common for walls, standard latex paints may not offer sufficient durability or water resistance for an aquarium stand without multiple coats of a robust sealant.

It is advisable to choose finishes that are certified as low-VOC or zero-VOC once fully cured, ensuring no harmful fumes are released into the air around your aquatic inhabitants.

Aesthetic Elements: Trim and Decorative Panels

Adding trim and decorative panels can transform a basic aquarium stand into a piece of furniture that complements your interior design. These elements provide visual interest and can help conceal the utilitarian aspects of the stand.The application of trim and decorative panels can be achieved through various woodworking techniques, allowing for a wide range of customization.

- Applying Trim: Trim can be added to the edges of the stand, around cabinet doors, or as decorative accents on the front and sides. Common trim profiles include quarter round, cove molding, and decorative wood strips. These are typically attached with wood glue and finishing nails or brad nails, followed by filling the nail holes and sanding smooth before painting or staining.

- Adding Decorative Panels: For a more elaborate look, consider adding panels to the cabinet doors or the sides of the stand. This can be achieved using beadboard, routed panels, or even inset decorative inserts. These panels are usually glued and sometimes nailed into a recessed area or frame.

- Door and Drawer Fronts: If your stand includes doors or drawers, you can enhance their appearance by adding decorative hardware, raised panels, or even a different wood veneer to the front surfaces.

Before attaching any decorative elements, ensure they are securely fastened and that any gaps are properly filled and sanded to create a seamless finish.

Reinforcing for Heavier Aquarium Setups

Aquarium stands must be engineered to support the immense weight of water, substrate, and equipment. For larger or heavier setups, additional reinforcement is essential to prevent structural failure and ensure safety.Reinforcement strategies focus on increasing the load-bearing capacity of the stand through added bracing, thicker materials, or strategic support placement.

- Additional Bracing: For tanks exceeding 50 gallons, consider adding diagonal bracing between the legs and the top or bottom panels. Metal L-brackets can also be used to reinforce the corners where the top panel meets the vertical supports.

- Thicker Wood: If you anticipate housing a very large or heavy aquarium, opt for thicker plywood (3/4 inch or more) for the top and bottom panels, and use 4×4 posts or doubled-up 2x4s for the main vertical supports.

- Central Support: For longer tanks (e.g., 75 gallons and above), a central support beam running from the front to the back, directly under the middle of the tank, is highly recommended. This distributes the weight more evenly and prevents the tank’s bottom from bowing.

- Reinforced Top Panel: The top panel of the stand is under immense pressure. For heavy tanks, consider using a double layer of plywood for the top, or a solid piece of hardwood. Ensure the top panel is securely attached to the frame with screws and glue.

When reinforcing, always consider the distribution of weight. The goal is to ensure that no single point of the stand is overloaded. For very large aquariums (e.g., 100 gallons and above), consulting with a structural engineer or using pre-designed heavy-duty stand plans is a wise precaution.

Essential Considerations for Aquarium Setup and Safety

Once your DIY aquarium stand is built and beautifully finished, the next critical phase involves ensuring a safe and stable environment for your aquatic inhabitants. This section focuses on the essential steps and considerations that bridge the gap between a sturdy stand and a thriving aquarium, prioritizing both the well-being of your fish and the longevity of your setup.

Aquarium Stand Leveling

Achieving a perfectly level aquarium stand is paramount to preventing undue stress on the glass tank, its seals, and the stand itself. An uneven surface can cause the weight of the water and substrate to distribute unevenly, leading to potential leaks, cracks, or even catastrophic tank failure. This is particularly important for larger aquariums where the sheer volume of water exerts significant pressure.To ensure your stand is level, utilize a spirit level.

Place the level on the top surface of the stand in multiple positions: front to back, side to side, and diagonally. If any bubble indicates an incline, you will need to make adjustments. Shims, which are thin pieces of material, can be used to raise specific corners or sides of the stand until it is perfectly level in all directions.

Wood, plastic, or even rubber shims can be effective, depending on the type of flooring and the degree of adjustment needed.

Aquarium Securing to the Stand

While most aquariums, especially those with silicone-sealed glass, are designed to sit securely on a flat surface, there are instances where additional securing might be beneficial, particularly for very large tanks, high-traffic areas, or in homes with pets that might bump into the aquarium. The primary goal is to prevent any accidental shifting or tipping.For most standard glass aquariums, a non-slip mat placed between the tank and the stand can provide extra friction and stability.

These mats are typically made of dense foam or rubber and are designed to absorb minor vibrations and prevent sliding. If you are building a stand for a particularly heavy or unusually shaped tank, or if you have concerns about seismic activity or accidental impacts, consider incorporating small brackets or straps. These should be discreetly attached to the stand and the bottom rim of the aquarium, ensuring they do not put direct pressure on the glass or seals.

Always consult the aquarium manufacturer’s recommendations for any specific securing requirements.

Electrical Cord and Equipment Management

The management of electrical cords and equipment is a critical aspect of aquarium safety, preventing hazards like water damage to electronics, tripping risks, and potential electrical fires. A well-organized stand interior can significantly enhance both the aesthetics and safety of your aquarium setup.It is highly recommended to use a drip loop for all electrical cords that plug into outlets. This involves allowing the cord to hang down in a loop below the outlet before it connects to the device.

This simple measure ensures that any water dripping down the cord will fall to the floor rather than running into the electrical socket.Consider installing a power strip with surge protection inside the stand. This centralizes all your equipment connections and provides an added layer of protection against power fluctuations. Use cable ties, Velcro straps, or conduit to bundle and organize cords neatly, preventing them from becoming tangled or posing a tripping hazard.

Ensure that all electrical components are kept away from any potential water sources, such as filter overflows or accidental spills. Ventilation is also key; ensure there is adequate airflow within the stand to prevent electrical equipment from overheating.

Common Construction and Setup Mistakes

Avoiding common pitfalls during both the construction and setup phases of your DIY aquarium stand will save you time, effort, and potential costly repairs. Awareness of these mistakes can help ensure a successful and long-lasting aquarium environment.Common construction mistakes include:

- Inadequate structural support: Failing to account for the immense weight of a filled aquarium, leading to sagging or structural failure of the stand.

- Improper joinery: Using weak adhesives or fasteners, or not ensuring joints are square and secure.

- Ignoring wood treatments: Not sealing or finishing the wood properly, leaving it vulnerable to moisture damage and warping from humidity.

- Lack of ventilation: Building an enclosed stand without considering airflow, which can lead to condensation and mold issues, and potential overheating of equipment.

Common setup mistakes include:

- Placing the stand on an uneven surface: As discussed earlier, this is a critical error that compromises the tank’s integrity.

- Overfilling the tank: Exceeding the manufacturer’s recommended water level can put undue stress on the tank’s rim and seals.

- Ignoring electrical safety: Failing to use drip loops, surge protectors, or proper cord management, creating fire or electrocution hazards.

- Rushing the setup process: Not allowing sufficient time for the aquarium to cycle properly before adding livestock, which can lead to fish stress and mortality.

- Not considering weight distribution: Placing heavy equipment or decorations unevenly within the tank, potentially stressing the glass.

Advanced DIY Aquarium Stand Features

![How To Build An Aquarium Stand [5 Easy Steps] How To Build An Aquarium Stand [5 Easy Steps]](https://langkahtepat.web.id/wp-content/uploads/2025/09/How-To-Build-An-Aquarium-Stand-5-Easy-Steps-scaled-1.jpg)

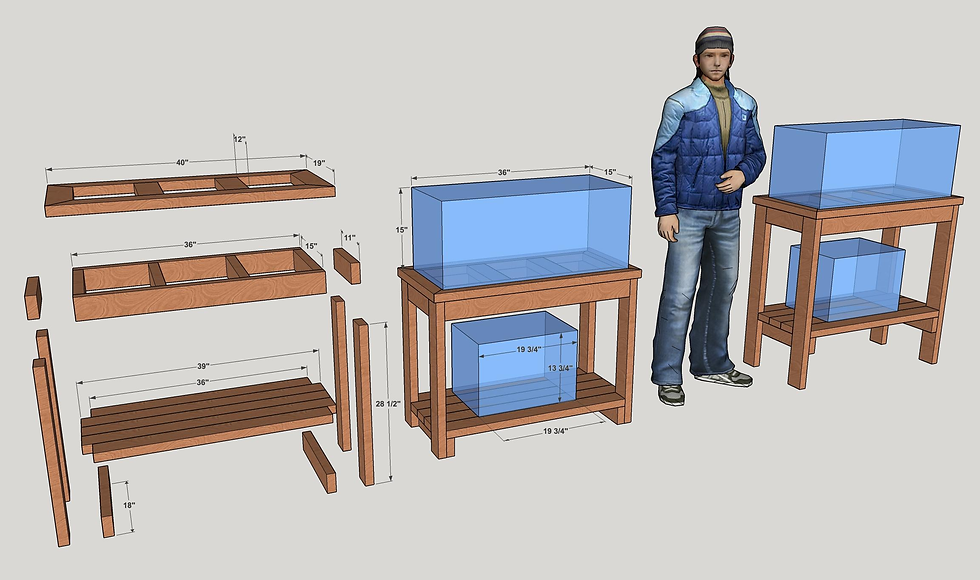

Moving beyond the foundational aspects of aquarium stand construction, this section delves into advanced features that can significantly enhance both the functionality and aesthetic appeal of your DIY project. These enhancements cater to specific aquarium types, integrate essential equipment, and allow for sophisticated design choices.

Integrated Sump Filtration Concept

Designing a DIY aquarium stand with integrated sump filtration offers a streamlined and aesthetically pleasing solution for managing water quality, especially for larger or more complex aquatic setups. A sump is a separate filtration system typically housed below the main display tank, allowing for discreet placement of pumps, heaters, protein skimmers, and media reactors. The core concept involves creating a dedicated, water-tight compartment within the stand’s lower section to house the sump.

This compartment needs to be accessible for maintenance and cleaning, while also ensuring adequate ventilation for equipment. The stand’s structure must be robust enough to support the weight of the sump itself, along with the water it contains, and the plumbing that connects it to the display tank. Design considerations include access panels, water-resistant materials for the sump compartment, and pre-planned routes for plumbing to and from the tank.

Structural Modifications for Saltwater Reef Tanks

Supporting a saltwater reef tank necessitates specific structural modifications to a DIY aquarium stand due to the unique demands of this environment. Reef tanks often house larger and heavier equipment, such as powerful return pumps, protein skimmers, and multiple media reactors, all of which add to the overall weight. Furthermore, the corrosive nature of saltwater requires the use of materials that can withstand constant exposure to salt spray and moisture.

This includes using marine-grade plywood or treated lumber, along with corrosion-resistant fasteners and adhesives. The stand’s design must also accommodate increased plumbing complexity, often involving dual overflows, separate return lines, and potentially dedicated plumbing for dosing systems or calcium reactors. Structural reinforcement, such as additional bracing and thicker wood, is crucial to ensure long-term stability and prevent any potential sagging or warping under the sustained load.

Incorporating Built-in Lighting and Cooling Systems

Integrating lighting and cooling systems directly into a DIY aquarium stand can elevate both the performance and visual appeal of your aquatic setup. For lighting, this often involves designing a canopy or frame that houses LED or T5 fixtures, ensuring they are positioned at an optimal height above the water surface. Ventilation within the stand is paramount when incorporating lighting, as heat generated by these fixtures can raise the ambient temperature.

This can be managed through strategically placed vents or by incorporating small, quiet fans to draw air through the stand. For cooling, especially critical in warmer climates or for sensitive marine species, dedicated cooling systems like aquarium chillers can be housed within the stand. The stand’s design must account for the chiller’s footprint, its electrical requirements, and the necessary plumbing for water circulation.

Adequate airflow around the chiller is essential for its efficient operation.

Modern, Minimalist Aquarium Stand Aesthetics

Achieving a modern, minimalist aesthetic for a DIY aquarium stand involves a focus on clean lines, uncluttered design, and the use of specific materials and finishes. One primary method is the use of sleek, flat-panel designs with concealed hardware. This often involves building a stand with simple geometric shapes, such as cubes or rectangular prisms, and utilizing hidden hinges and magnetic catches for any access doors.

Another approach is the “floating” or “wall-mounted” look, where the stand appears to be suspended or has minimal contact with the floor, creating an illusion of lightness and space. This can be achieved by designing a robust internal frame that attaches securely to the wall, with the visible portion of the stand being a minimalist facade.

Material Choices for Minimalist Design

The selection of materials plays a significant role in defining a modern, minimalist aquarium stand.

- High-Quality Plywood with Laminate or Veneer: This offers a smooth, uniform surface that can be finished in matte whites, grays, or blacks, or with subtle wood grains. The edges can be kept sharp and clean for a contemporary look.

- Metal Frames with Wood Accents: Combining powder-coated steel or aluminum frames with solid wood or high-quality laminate panels can create a striking industrial-chic or modern aesthetic. The metal provides structural integrity while the wood adds warmth.

- Acrylic or Glass Panels: Incorporating large, seamless panels of frosted or clear acrylic or glass can contribute to a sleek, almost invisible appearance, allowing the aquarium itself to be the focal point.

Concealing Equipment and Plumbing

A key element of minimalist design is the effective concealment of all unsightly equipment and plumbing. This is achieved through thoughtful planning during the design phase.

- Integrated Cabinetry: Design the stand with internal shelves and compartments that are completely hidden behind seamless doors or panels. These compartments should be sized to accommodate filters, heaters, pumps, and other necessary equipment.

- Cable Management Systems: Incorporate built-in channels, grommets, or magnetic cable clips within the stand to neatly route and hide all electrical cords.

- Plumbing Routing: Plan for internal channels or conduits within the stand to discreetly route all plumbing lines from the tank to the sump and back, ensuring they are accessible for maintenance but visually hidden from view.

Final Wrap-Up

In conclusion, constructing a DIY aquarium stand empowers you to create a robust and aesthetically pleasing home for your aquatic life. By carefully considering design, materials, and construction techniques, you can build a stand that not only supports your aquarium reliably but also enhances the overall appeal of your space, ensuring a safe and beautiful environment for years to come.